A bike frame is a complex of variously shaped tubes, and the angle of those tubes to each other mainly determines how a bike handles on the road or trail.

The head tube is not the most important of the tubes (top, down, seat, chain/seat stays); but there is none more important.

Over the past century of frame design, head tubes have been—mostly—symmetrical, having the same sized diameter, top and bottom.

In a tapered head tube, the lower diameter is wider than the upper.

In the following sections I explore

- the original tapered head tube

- how the tapered head tube works, and

- the reasons for using one

I also discuss how recent innovations in bike technology look like reducing the role of the tapered head tube in bike design where this type of head tube has, hitherto, dominated.

The switch to internal cable routing on high-end road bikes demands an oversized head tube of the same diameter top and bottom, as has been standard with mountain bikes in recent decades.

CONTENTS

The Function of Head Tube Geometry

Tapered to Non-Tapered and back to Tapered Head Tubes

Tapered Head Tube Manufacturing

Can You Convert a Straight Steerer to Tapered?

THE FUNCTION OF HEAD TUBE GEOMETRY

It’s firstly important to understand the basic principles of frame geometry as the background context for understanding the function of the tapered head tube.

Whether a bike has a tapered head tube or a standard head tube, the head tube’s angle determines how the bike handles.

Note that in this brief discussion, I’ll leave aside the effect of different sized wheel bases which takes into consideration FC and RC measurements as a part of the total equation determining bike handling.

Tapered head tubes were introduced to enhance stability and improve handling over and above the influence of head tube angle.

By ‘handling’, I mean the responsiveness of a bike’s steering to a rider’s changes in direction.

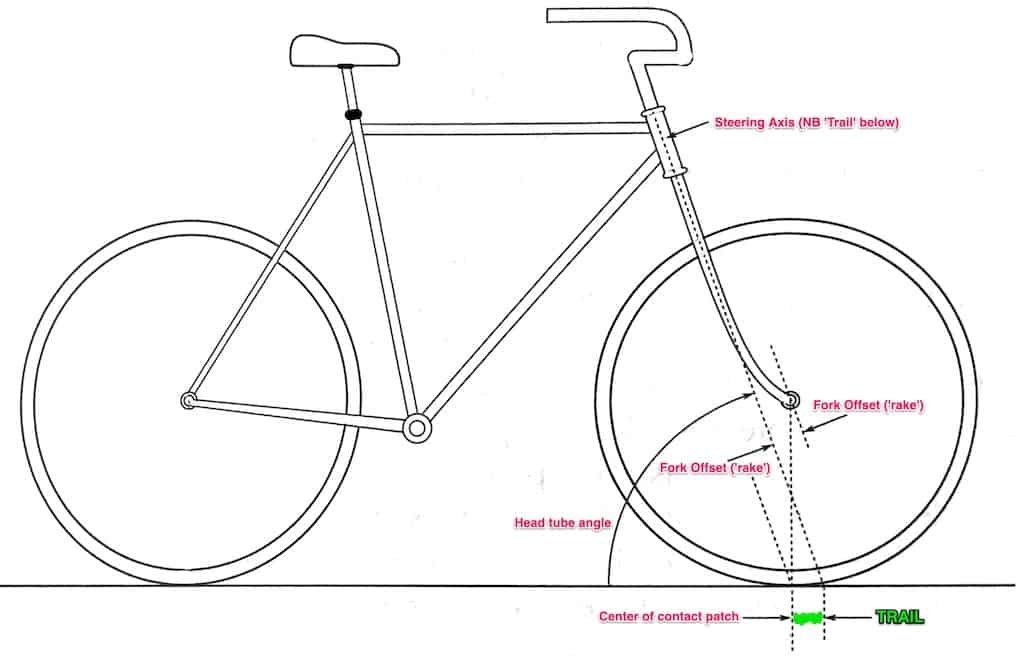

The crucial dimension (or technically, plane) is the steering axis, an imaginary line running through the center of the head tube forming an angle at the ground or pavement (assumed to be a perfectly horizontal plane).

The steering axis is determined at the point of manufacture, where the head tube is welded into the top tube and down tube with reference to the original geometrical drawing.

The head tube angle varies with the size of the frame. Smaller frames have sharper/slacker head tube angles in line with the length of the top tube and angle of the seat tube.

The trail is the distance between the the offset, or rake as it’s sometimes called, and the steering axis.

The smaller the trail—and thus the sharper the head tube angle—the more responsive the bike; “twitchy” is the term many cyclists would use to describe the ride quality.

The greater the trail, the less responsive and more laid back the ride quality.

Road bikes tend to have less trail for nuanced steering at speed, mountain bikes more since greater trail is more suitable for the varied terrain traversed by MTBs.

TAPERED to NON-TAPERED (and back) to TAPERED HEAD TUBES

Although the tapered head tube would appear to be a recent innovation in bicycle frame design and geometry, it seems to have been around since the beginning.

The Ordinary (Penny Farthing) was the first pedal-powered bicycle where the head tube and fork made up 50% of the frame, the remainder consisting of the top tube and rear fork.

If you take a close look at this Penny Farthing replica on display in Giant’s international HQ in Taichung, you’ll note that the head tube is, technically, tapered—slightly wider at the bottom compared with the top.

A close look at a number of antique models on display in museums shows similarly shaped head tubes.

After a decade or so, the Ordinary was superseded by the safety bike which incorporated a standard head tube in the conventional twin diamond frame that still dominates today.

Standard (Non-Tapered) Head Tube

Standard head tubes have the same diameter top and bottom.

They were originally designed for a 1” steel steerer, installed by means of a threaded headset.

The widespread adoption of integrated headsets and threadless headsets resulted in the increase of the head tube diameter to 1-1/8” top and bottom.

Tapered Head Tube – Tapered Fork

The period 2012-13 saw the mass adoption of tapered head tubes, which measured1-1/8” at the top and 1-1/2” at the base.

The benefit is the ability to accommodate a large tapered, oversize fork—more on its purported advantages below.

You also need an appropriate tapered headset of course.

This is an early example of a carbon tapered fork manufactured during the early 2010s when tapered head tubes were heading for mass adoption.

The carbon steerer is glued into a lug moulded into the fork crown, a design that was originally used in standard 1-1/8”, top and bottom, head tubes.

Enlarging the head tube’s base to 1.5” creates a taper to fit to a standard tapered head tube.

Or, rather, a tapered head tube is designed to accommodate a tapered fork.

Effectiveness of Tapered Head Tubes & Tapered Forks

Just about everyone has an opinion about the improvement—or not—of a bike’s handling under the influence of a tapered head tube.

The obvious argument is that a tapered fork’s wider steerer at the fork crown is stiffer, resulting in a more responsive or efficient ride.

Since the head tube is larger at the base where the down tube connects, It also allows a larger down tube which enhances the overall stiffness of the frame, especially since the the area housing the BB shell can be massively reinforced to resist pedaling torsion.

The problem is one of making an objective assessment in light of the number of variables that influence bike handling, such as overall frame geometry and tire width and type.

For an accurate “apples to apples” comparison, you really need two bikes, absolutely identical in all aspects, one bike with a standard head tube, one with a tapered head tube.

Riding each bike over the same road or terrain in the same conditions would then provide a basis for comparison.

RETHINKING TAPERED HEAD TUBE DESIGN

There has been a recent revolution in (high end) road bike frame design that began with

- the move to electronic shifting and

- crafting more aerodynamic frames

Road bikes have either full internal cable routing or semi internal cable routing, both of which require an oversized head tube with the same diameter top and bottom.

So from the relative dominance of tapered head tubes, bicycle design has now returned to head tubes with equal sized top and bottom diameters.

The head tube must be wide enough to accommodate the cable housings, which need to easily fit (for quick installation) between the tube wall and the steerer without impeding the rotation of the steerer.

The diameter of both the upper and lower head tubes is 1.5”, although the feedback from the market is that, despite the functional advantages, it’s not such a good look (certainly a matter of opinion).

The preference seems to be to keep the upper diameter at 1.5” and increase the lower diameter to 1.8”.

And with that, we’re back in tapered head tube territory.

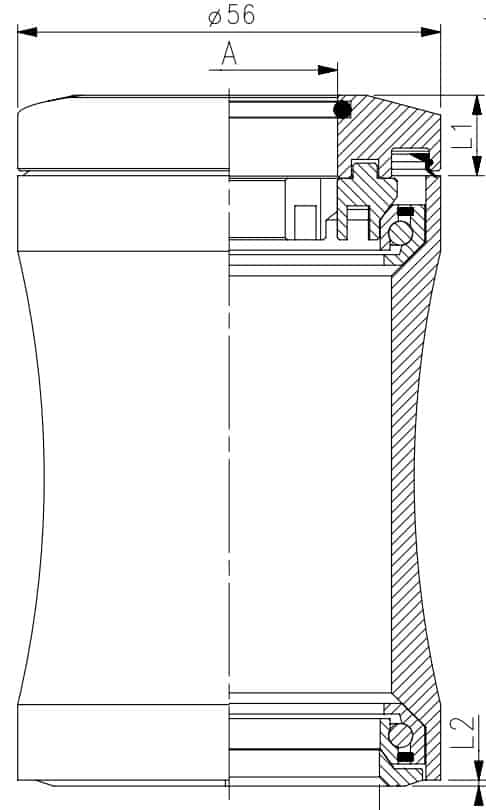

An example is this carbon eMTB frame from Carbotec which incorporates a tapered head tube.

The head tube was already oversized thus allowing for the massive down tube that’s necessary to house the large battery.

And enlarging the base to create the tapered head tube makes an even beefier down tube possible.

Looking at this head tube’s anatomy, you’ll firstly note there’s no built-in flange for the sealed bearing.

This latest iteration of tapered head tube design draws from the pre integrated headset days, where bearing cups were inserted top and bottom as bearing containers.

The internal cable routing headset bearing cups for this head tube are inserted with light taps from a rubber mallet with the compression ring, spacer(s), dust cap, and bearings of the integrated headset performing the same function as in other headsets, although they are oversized in comparison.

Some cyclists may be concerned over the added weight. But since this bike is a mid-drive eMTB, weight issues are cancelled out.

TAPERED HEAD TUBE MANUFACTURING

Tubing for steel, chromoly, or alloy bike frames is made by specialized tube companies such as Ming Huei (a traditional manufacturing firm that does not have a website) and Nan Long two amongst several tube manufacturers.

A brand that builds frames or complete bikes obtains the tubes from one of these companies then either welds the frame themselves (rare), or outsources welding to a specialist factory (the standard practice).

Head tubes require cut outs where the top tube and down tube weld into them (ditto for bottom bracket shells by the way).

The manufacturing procedure for carbon fiber is radically different—layers of carbon fiber sheeting are bound together in one mold to create a singular unit.

The tapered “head tube” is actually one cavity amongst many within the ‘shell’ that is the frame.

Note how the head tube is merely an extension of the frame; the head tube walls merge into the top tube and down tube.

You can see that a (tapered)head tube is actually defined by its function, not its form.

A head tube, tapered or not, is defined by the angle forming the steering axis which creates the trail allowing a bike to work.

That angle is defined by the degree of forward offset of the center lower diameter’s center point in relation to the center of the upper diameter.

The head tube sets the stage; but its magic resides in its intangibles geometry, not in its status as a ‘tube’.

CAN YOU CONVERT A STRAIGHT STEERER TO TAPERED (OR VICE-VERSA)?

A fork with a straight steerer by definition is not a tapered fork.

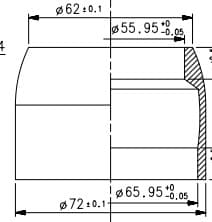

A non-tapered fork fits a standard 1-1/8” head tube (top and bottom), whereas a tapered fork is designed to fit the taper which measures 1.5” ie. 1-1/8” top, and 1.5” bottom.

You can fit a straight fork to a tapered head tube with an adapter, a crown race reducer. But, of course, a tapered fork cannot be adapted to fit a standard head tube: 1-1/2” won’t fit into the smaller diameter 1-18”.

A crown race reducer, such as this one from Cane Creek, is simply a thicker crown race which fills the 1/8” gap between the straight fork crown and the wider ID of the tapered head tube.

FINAL COMMENTS

The tapered head tube is a recent development in bike design.

Standard in road bikes, tapered head tubes were superseded with the uptake of internal cable routing, which required making a tapered head tube’s upper diameter the same size as the lower diameter to accommodate the cables.

Head tube tapering is now re-appearing in some frame designs, however, though more for aesthetic than functional reasons, as internal cable routing and the rapid uptake of ebikes dominates bike design and builds.