A bike’s bottom bracket—or “BB”—together with the rear sprocket and chain constitutes the drive train.

This article describes the most common BB types, many of which we have covered in detail in individual posts on FIRST’s blog.

Skim through the headings for an overview, then skip to the section that interests you.

CONTENTS

THREADED BIKE BOTTOM BRACKETS

Bsa BBs

Square Taper

Cartridges

Outboard Threaded

Bmx

Eccentric

T47

Sram Dub

PRESS FIT

BB30

BB86/92

Pf30

ADAPTERS

OTHER STANDARDS

THREE CATEGORIES

Bike bottom brackets are divided into threaded bottom brackets, press fit models, and adapters/converters.

Cheaper bikes are usually fitted with threaded BBs; more pricey bikes—especially high end ‘racing’ bikes—use press fit.

Adapters transform press fit BBs to threaded or threaded to press fit, often to fix a malfunction or to enable the fitting of a specific crank: using an adapter avoids having to buy a new bike or at least a new frame.

THREADED BIKE BOTTOM BRACKETS

The type of bike bottom bracket you’ll find on a low to mid-end model has threaded cups which match a corresponding threaded bottom bracket shell.

The cups contain loose, caged, or sealed bearings within which a spindle, which carries the cranks, rotates.

NOTE: it’s a spindle and not an axle, since axles do not rotate but remain fixed as bearings rotate around them.

BSA BB

“BSA” is the all-inclusive term often used to refer to threaded bottom brackets as a group.

“English” threaded is also a common way of referring to the group, and, technically more accurate.

“BSA” is short for Birmingham Small Arms, a British company whose core business was manufacturing light weapons.

BSA moved into the bike business during the1880s as bicycles and cycling began to become popular in the lead up to the 1890s bicycle boom.

The company continued to make bicycle components well into the 20th century, so the term “BSA” stuck.

The specification is 1.37” diameter with 24 threads per inch.

Square Taper BB

The square taper design is the bike bottom bracket that came to dominate the BSA/English threaded category, which it still does today.

The four angled faces accommodate a crank with a matching aperture, squared and angled in the opposite direction, with one bolt holding it in position on the spindle.

Cotter pins were a transitional design to the modern square taper.

A cup and cone contained the bearings with the crank holding tight to the spindle, so long as the cotter pin bolt was kept tight.

The beauty with this simple and functional bike bottom bracket was the only tool you needed was the right sized open-ended or ring wrench, although cotter pins could get stuck after decades (!) in position requiring extra ingenuity to remove them.

After that, a screwdriver and hammer will loosen the lockring—out with the cottered crank.

You could opt for a cup and cone bearing setup with a square taper spindle.

The beauty of this design is that bolts replace the cotter pins, although the added complication is the crank extractor tool that you now require to remove the cranks.

The complete process is detailed in the video.

Cartridges Rule

Square taper BBs almost exclusively come in a cartridge form nowadays.

Sealed bearings are pressed into a container around the spindle. The whole

This one is unique, though, since you can use it with a set of ruined threads.

Supposing an incompetent bike shop pro has ruined your bike’s BB shell’s threads to the point where they are unable to be repaired.

This unit presses into the shell over the top of the stripped threads.

Outboard BSA BBs

Integrated cranks do away with the cartridge method of integrating the spindle into the bottom bracket.

Instead, a 24 mm spindle is fused to the drive side crank; the bottom bracket turns into a set of bearing cups relocated outside of the BB shell and connected within the shell by an alloy or nylon sleeve helping to keep dirt and moisture out of the sealed bearings.

Apart from a lighter crank, this setup enabled the use of larger bearings which were more durable than the smaller units installed in cartridges inside the BB shell.

BMX

A BMX bike bottom bracket will be either a

- cheap and fairly rough loose/caged bearing one piece setup or

- three piece square taper solution

The simplest BMX BB takes a one piece crank—clunky, heavy, and not very efficient, let alone cool!

By far the better way to go is to install a three piece setup..

The bearing setup is the same as used with the one piece crank. The difference is you now have a single spindle with lighter and much cooler looking cranks.

You also have a wide choice of cranks that you can fit as well.

Another way to change from one piece to three piece is to remove the bearing cups then fit a self-installing adapter that takes a square taper cartridge.

The idea is to loosely mount these cups into the now empty BB shell.

The Allen bolts insert from the drive side and screw into the non-drive side cup

Tightened into position you install a cartridge BB as normal.

Eccentric

Most bike bottom brackets are concentric: the spindle revolves evenly around the BB’s centerpoint.

Eccentric BBs (henceforth EBB) rotate away from the BB’s center point, which gives a cyclist a quick way to change the position of the crank: as you rotate the bottom bracket, the crank simultaneously moves up or down and forward or back.

You install an EBB on a single speed to make tensioning the chain quick and easy.

An EBB on a mountain bike enables the rider to alter the height of the crank to help negotiate tricky trail conditions or other purposes.

EBB’s are available in threaded or non-threaded versions.

FIRST released a new type of threaded EBB into the market in 2019 that has gained wide acceptance and sells well on the website.

This bike bottom bracket’s core fits a standard BSA bottom bracket shell; the eccentric outer unit rotates around this main core.

Three bolts prevent the eccentric outer unit rotating.

A rider is easily able to change crank height or chain tension by loosening each of the three bolts on each side with a 3 mm Allen wrench.

Rotate this outer unit to the desired position, then re-tighten the six bolts.

T47

T47 is the most recent threaded bike bottom bracket standard to arrive in the market.

T47 represents a turn away from the dominant press fit style of bottom bracket which has come in for plenty of criticism over the years.

The particular BB that T47 targets is PF30, which was itself a result of trying to solve the problems with a range of preceding press fit BB models.

T47 is the culmination of an evolution from the first press fit design, BB30, which expanded the English threaded 34.8 mm internal diameter to 42 mm, ending with PF30’s 46 mm.

In the early 2000s, Chris King set out to actually solve a problem, rather than introduce yet another standard for the sake of innovation.

The standard first appeared in 2015 to plenty of skepticism but heading into the 2021 model year, Trek and Specialized announced the introduction of bikes sporting T47 setups.

A clear advantage of T47 over BSA is the larger bearing.

Modern BSA cartridge BBs use a sealed bearings that last longer and perform better than loose cup and cone bearings.

Sealed bearings, however, are still packed into the same 34.8 mm space of the BB shell.

T47 grants an extra 11.2 mm of internal diameter—a whole extra centimeter!—allowing a much larger bearing.

Moreover, you can boost that a little further with an external bearing model.

T47 permits cyclists to install the largest bike bottom bracket bearings ever in the history of bottom bracket design. Very good news indeed.

SRAM DUB

SRAM’s Dub standard, introduced in 2018, can be understood as a reaction to the proliferation of standards plaguing bike bottom bracket development over the last two decades.

The Durable Unified Bottom bracket firstly notes the importance of a 30 mm crank spindle: it’s lighter and stiffer than cranks using 24 mm spindles.

Instead of a strictly 30 mm spindle, the diameter decided upon was a whisker under 29 mm at 28.99 mm.

SRAM argues that achieving exacting tolerances, 28.99 mm rather than 30 turned out to be the optimum spindle diameter.

DUB allows cyclists with BSA, BB30, BB86/92, or PF30 to install the one 28.99 mm crank (read 30 mm) in their rig.

No matter what bike you have or what BB spec you are stuck with, you can enjoy a stiffer and lighter crank by simply swapping out your current BB for the correct size.

Fitting or removing the press fit versions of this standard can be achieved via FIRST’s toolset designed just for SRAM DUB.

The DUB BSA BB can be installed and removed with tools already on the market although not for the press fit versions.

The toolset’s various components fit 41, 42, and 46 mm BBs.

Removal does not require impact tools which are widely used to bash a BB bearing cup out of the BB shell.

Taking a hammer and chisel approach can severely damage a bearing cup making it unusable in another bike.

PRESS FIT

A press fit bike bottom bracket fits tightly into a non-threaded BB shell.

The goal was not to introduce a new BB standard though. The target was—initially anyway—to allow the use of a stiffer and lighter 30 mm crank spindle.

Once press fit gained acceptance amongst cyclists, later years saw a proliferation of press fit models and specifications.

BB 30

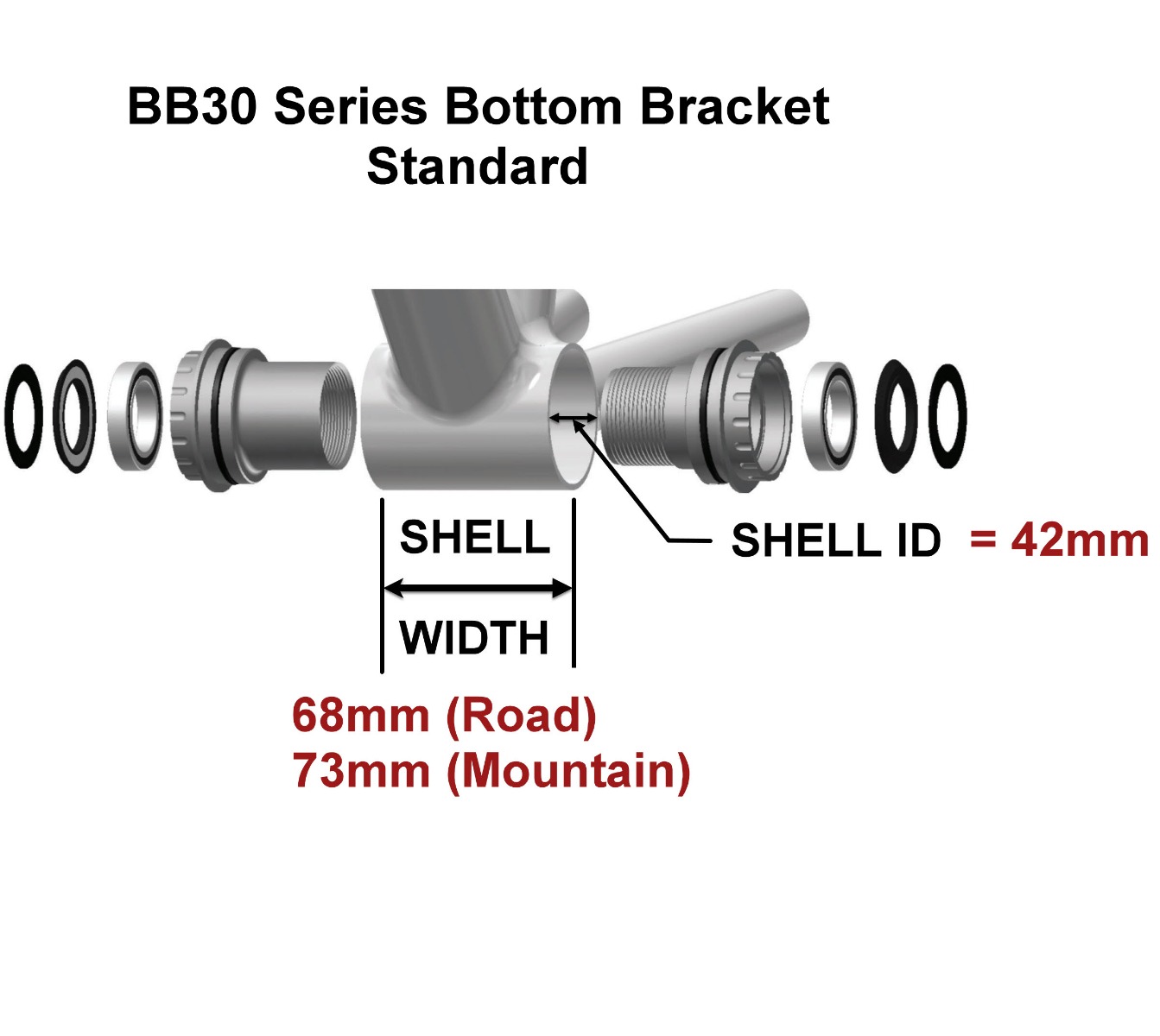

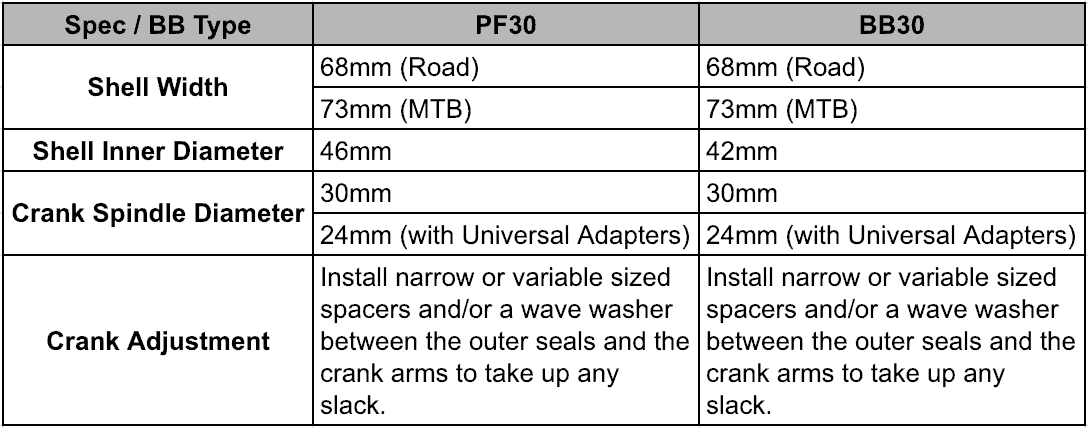

The BB30 bike bottom bracket is so named as it was designed to enable the fitting of a 30 mm spindle crank to replace the standard 24 mm type.

The BB shell internal diameter expanded to 42 mm from the threaded standard’s 34.8 mm, with the sealed bearing directly fitted into the shell.

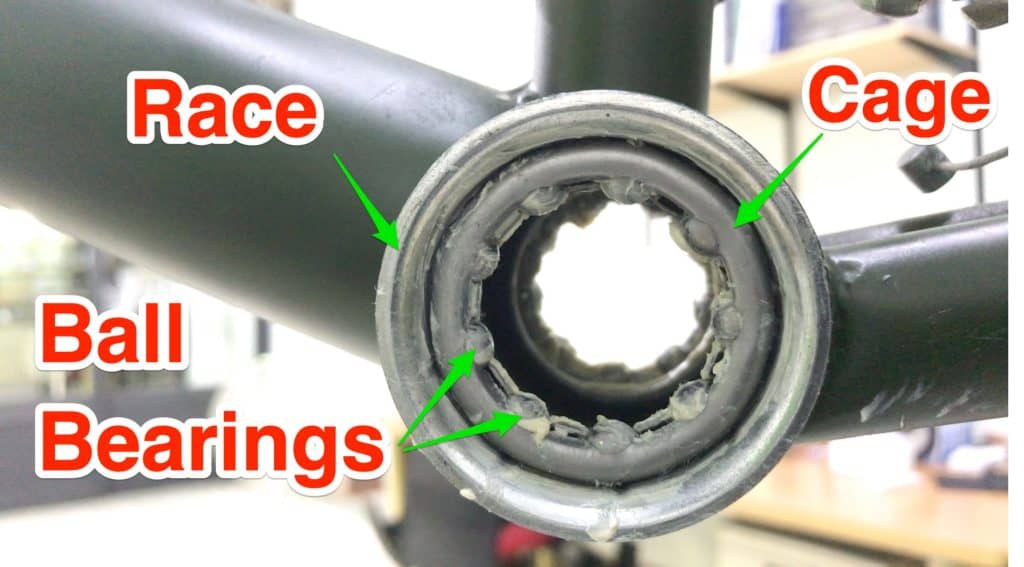

In a sense this is a looking back to the days when bearings consisted of loose ball bearings sitting against a cup and constrained by a cone tightened against them.

The difference is that caged bearings sit in an alloy container topped off with the rubber seal, which is then seated in the shell.

Difficulties

The problem with this setup is that the bearings are not seated as securely into the BB shell compared with threaded BBs which slot immovably into the shell—small movements resulted in creaking bottom brackets in many cases.

You also need a range of specialized tools to install and then to remove the C clips as well as the bearings themselves.

Tolerances are extremely tight. So the fitting must be exact otherwise bearing movement against the shell is guaranteed thus creating the notorious creaking associated with press fit BBs.

BB86/92

The BB86/92 standard was the next step in press fit evolution.

Instead of sealed bearings fitted directly into the BB shell, they are mounted in cups which are then pressed into a 41 mm non-threaded shell.

“86”(mm) is the width of the cups combined with the standard road bike shell width of 68 mm; “92”is the width of the cups combined with the standard mountain bike shell width of 73 mm.

Installation and removal is much more simple than BB30, although the impact method of removal is the dominant means of removing the cups.

FIRST’s BB2430 press fit toolset removal function relies on gentle pressure to both install and remove the bearing cups.

The split steel-hitch is the key.

It expands around a driver that braces against the side opposite to the side from which you are removing a cup.

The steel-hitch’s flange braces against a bearing cup’s interior face: turning the driver pushes the cup out of the BB shell.

A bolt connecting brackets on both the drive and non-drive side is the way to gently press-install the cups into the BB shell.

PF 30

Press Fit 30 is best understood as a reaction to BB30

This standard was designed as a solution to the problems associated with BB30, particularly the exacting tolerances associated with directly installing into the BB shell, in the context of enabling the use of a 30 mm diameter spindle.

The PF30 increases the BB shell’s internal diameter from 42 mm to 46 mm, the largest shell size of any bike model apart from BMX.

Sealed bearings mounted in cups are then pressed into the BB shell in the same way as BB86/92 BBs. The key difference is a 46 mm BB shell ID vs a BB86 41 mm ID.

Installation and removal is easily carried out in the same way.

The toolset is also similar: a center bolt and brackets to press the cups in and a split steel-hitch used with a driver to remove the bearing cups.

Self-installing and self-extracting models are also an option.

This design consists of two elongated cups, where the drive side is longer than the non-drive side and threads into the non-drive side.

You use a wrench supplied with the unit to alternate between the drive and non-drive sides to turn the cups, pulling both sides into position.

To remove, just loosen each side in turn, unscrew, then remove.

In spite of PF30’s origins as a way to enjoy the benefits of a 30 mm spindle crank without BB30’s issues, once again a problem with tolerances emerged.

Most cyclists installing a PF30 unit won’t have a problem. A significant minority will experience creaking BB syndrome since frame manufacturing tolerances vary widely and PF30 units that fit perfectly into one frame will not fit as well into another.

The differences may be only in the order of a few tenths of a millimeter—but such minuscule discrepancies are often the source of problems.

One answer to this has been to add threads to 46 mm BB shells—thus we arrive at the T47 bottom bracket specification as discussed above.

BIKE BOTTOM BRACKET ADAPTERS/CONVERTERS

BB adapters, or converters, give a bike owners greater flexibility in installing BB and crank setups that their bike is otherwise unable to accommodate.

They are probably most used to adapt 46 mm or 42 mm BB shells that are designed to take 30 mm cranks to take 24 mm cranks.

Adapters are most widely available in these three forms: press fit cups without sleeves; self installing/extracting models and cup with sleeve; and full sleeves with expanding friction bands or a similar mechanism.

Installing and removing press fit cups can be done with the toolsets mentioned in the sections on BB86 and PF30.

All you need for installing the expanding band model is a 3 mm Allen wrench.

Then install BSA cups into it ready to take a 24 mm crank.

Or, you could install T30 cups into which you could re-install a 30 mm crank, if there was an intractable problem with the original PF30 BB.

Adapters are available to used creatively to expand a bike’s possibilities, without having to go to the extreme of purchasing a new bike in order to overcome component or compatibility issues that have arisen during use.

OTHER STANDARDS

There are a number of bike bottom brackets (mainly for road bikes) not mentioned above since they are were mainly brand-specific variants within the major categories and have mostly been discontinued. Not knowing these will not impact your life in any way, shape or form…

BB30A and BB30-83 Ai

Cannondale’s proprietary standard. Basically a BB30 setup. BB30A is 73 mm; BB30-83 Ai is 83mm. The shell is wider on the drive side than the non-drive side.

BB90 and BB95

Trek’s proprietary design. BB shell ID of 37 mm to take a 24 mm crank however. Width of 90 mm for road, 95 mm for MTB.

BB386 EVO

FSA design PF30-ish with BB shell width of 91.5 mm

BBRight

BB30 just for road, 79 mm width. Drive side BB shell wider than non-drive side.

PF30A and PF30-83 Ai

Cannondale. A PF30 version of BB30A and BB30-83 Ai above.

OSBB

Specialized: the road version is BB30, 68 mm shell width; MTB version basically a PF30 spec.

Thread Fit 82.5

Colnago’s proprietary BB86-ish design.