Keep reading for a detailed coverage of

- the main types of MTB bottom brackets you are likely to come across on MTBs, past and present

- the tools you need (and how to use them) for installation, removal, and maintenance

There is a lot of crossover between MTB bottom brackets and the BBs installed on most folding, hybrid, and cruising bikes not meant to be taken off-road.

So much of the info here applies to those models as well.

CONTENTS

MTB Bottom Bracket Types: Threaded vs Press Fit

MTB Bottom Bracket Tools: Advice on Selection and Use

A Unique MTB BB (truly unique…): How to Install and Use

MTB Bottom Bracket Types

There are two types: threaded and press fit:

- Most modern threaded mtb bottom brackets are English threaded (BSA).

- Low end bikes use cartridge BBs; mid- to high-end models have external cups.

- Otherwise T47, a threaded alternative to press fit, are an increasingly popular option

- Press fit began with sealed bearings seated directly in the bottom bracket

- Sealed bearings seated in cups pressed into the BB shell now dominate

MIT GEWINDE

PATRONEN-TRETLAGER bottom brackets are installed on low end, entry level MTBs.

They were a major innovation when originally introduced—no more cup, cone, and cotter pins:

- insert bearings and spindle as one unit

- remove the whole unit when the bearings wear out

- bolt the cranks directly onto the spindle

The problem is that the (sealed) bearings are less durable as they must fit into a space smaller than the bearings in the original cup and cone configuration.

Larger bearings are not subject to the same degree of wear as smaller bearings.

External BBs improved on cartridge BBs and are mostly for mid- to high-end MTB models.

The sealed bearings which sit outside the BB shell are larger and can be replaced if you have the tools—and the skills

Prying them out and re-seating them perfectly is tricky to accomplish without damage to the sealed bearings.

Even slightly excessive side load can cause mis-alignment between the upper and lower races meaning the bearing has to be replaced.

The easier route is to replace the cup or cups.

T47 has become an option in the late 2010s as the move away from press fit complexity to threaded simplicity continues to gain momentum.

Press Fit

The bottom bracket’s bearings are pressed directly into the BB shell or mounted in cups which are then pressed into the shell.

DIRECTLY PRESSED: BB30

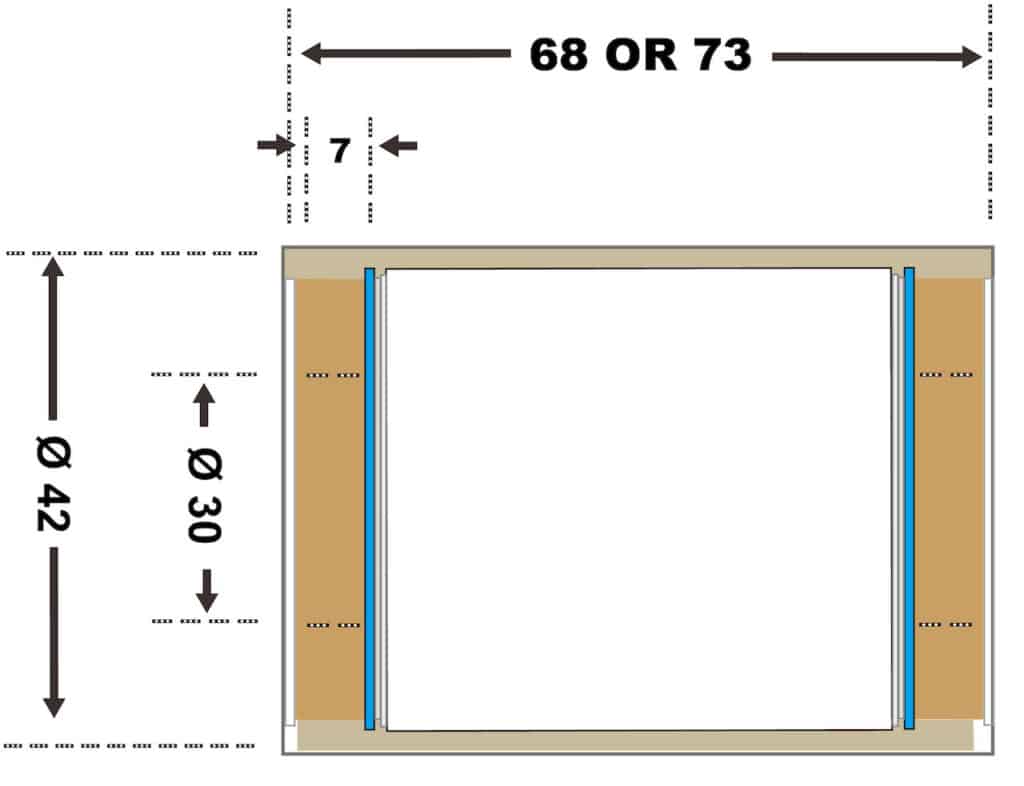

The press fit revolution began with sealed bearings seated directly in the BB shell in the form of the BB30 standard.

The sealed bearing sits against a lip machined into the BB shell and is held in place by a C-clip for most brands: BB30; BB30A & BB30-83 A; OSBB (Road); and BB Right (Direct Fit version). Trek’s BB90/95 does not use a C-clip.

The press fit innovation aimed at enlarging bottom brackets to accommodate a 30mm diameter spindle which required increasing the BB shell diameter to 42mm.

A 30mm spindle is stiffer and lighter than the 24mm integrated spindles they replaced, an advantage for MTB (and road) racers looking for an edge.

Problems with BB30-style press fit are well documented. While many cyclists are happy with their BB30 rigs, many are not.

This Reddit thread showcases a cross-section of opinion and touches on the various techniques mechanics use to smooth over BB30’s problems.

Despite Cannondale introducing and popularizing BB30 some 20 years ago, in early 2022 the brand shifted their Synapse model from BB30 to the BSA threaded standard.

Press fit enables—and even encourages—multiple standards in a way that threaded does not. English threaded is the most widely used by a long way; a small minority uses Italian and French threaded models. Add T47 to the mix and that’s as complicated as it will get.

PRESSED IN CUPS: BB86/92 & PF30

Making BB30 work with minimal problems requires:

- VERY finely machined parts

- specialist tools

- the skill to use those specialist tools

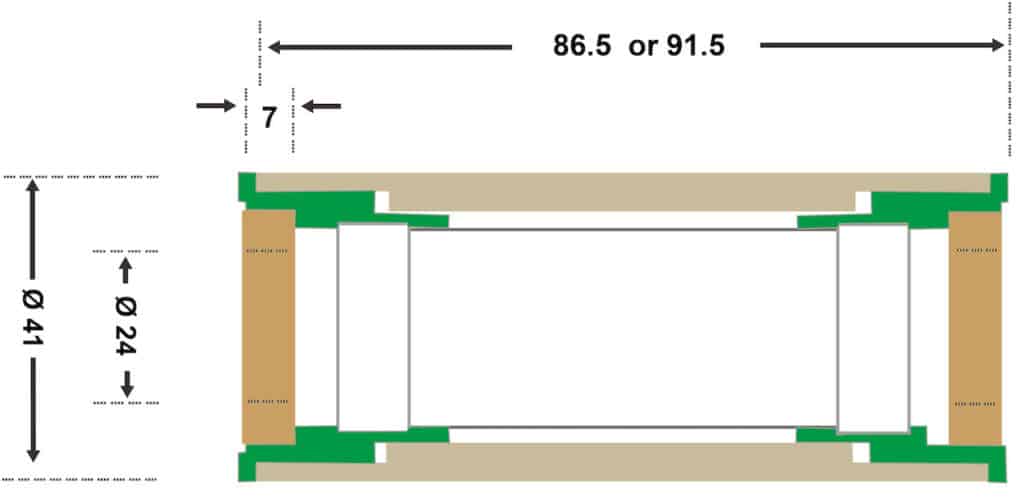

BB86/92 sealed bearings are placed in cups which are then pressed into the BB shell.

The difference with BB30 is that the 24mm spindle is retained, and the cups are pressed into a BB shell with an ID of 41mm.

BB86/92 relocates the bearings back inside the BB shell, which means the bearings are slightly smaller compared to external BBs.

PF30 was SRAM’s attempt to improve on BB30 by keeping the 30mm spindle and placing the sealed bearings in cups—BB30 except in cups if you will.

That required a BB shell with an ID of 46mm to accommodate both a 30mm spindle and the cups to house the bearings.

Problems with PF30 again concern manufacturing precision: the manufacturing tolerances of BB shells vary widely among manufacturers.

Plus, BB shells are never perfectly circular—putting together parts that are not specifically machined to go together almost guarantees that the cups will move in the shell.

The progressive return to threaded in the form of T47 and dependable BSA/English threaded models solves that problem—if you’ve got a creaking or clicking problem, then the bearings are worn or the pedal bearings are worn.

MTB Bottom Bracket Tools (practical advice)

To service a bike there are the tools you want . . . and the tools you need.

Take note of these three facts:

- the more tools you have, the easier (most) jobs become

- the range of tools is increasing every year

- tools are dead easy to obtain (Amazon) and usually cheap.

That’s a recipe for buying a lot of tools you don’t need (like so many other gadgets we accumulate) and probably won’t use even once.

Avoid this by taking into account these considerations:

- The key tasks are installing, maintaining, and removing the BB

- Is your MTB bottom bracket threaded or press fit?

Installing, Removing, and Maintenance

A correctly installed MTB bottom bracket won’t need attention until there’s a problem with the bearings or cups in the form of looseness or creaking.

Maintenance, then, nearly always means removing the bearing or cup to work on it.

And that means you need a specialist removal tool; which type of tool depends on whether you have a threaded or unthreaded BB shell.

Threaded vs Pressfit

Threaded BBs are the most simple since they are limited to just a few types whereas the press fit standard includes a wide variety of branded interpretations of the standard.

That has in turn resulted in a wider variety of tools to deliver the greater precision required to work with press fit systems.

The main problem with threaded BBs is cross threading which is easily avoided by going slowly and being attentive through the installation process.

Press fit bearings and cups are also easily installed—removal, however, is more complicated.

MIT GEWINDE

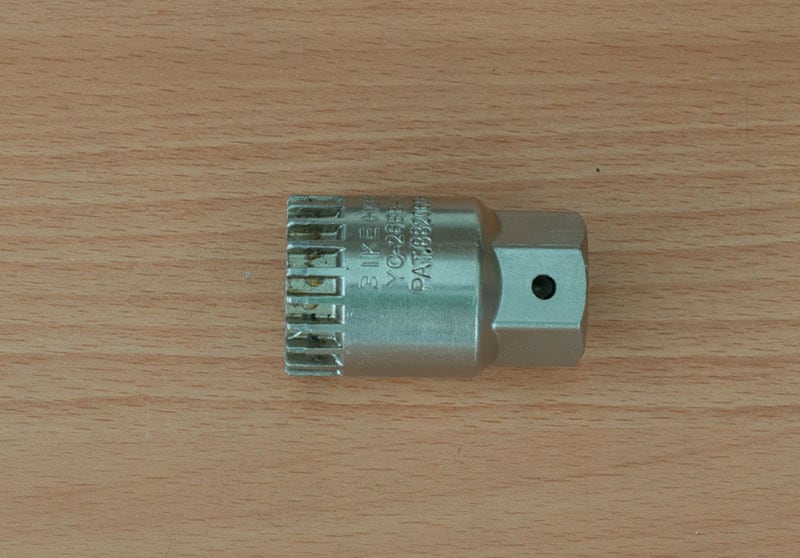

Cartridge BBs require a splined socket which normally fits a 0.5” driver that inserts into the cartridge’s splines.

External cups require a socket or a ring wrench that fits over the cups .

The important skill is holding the wrench square on the splines or teeth when applying pressure to the handle—the teeth can easily slip. Using a socket makes the job easier.

PRESSFIT

Pressfit systems are more complicated due to the number of branded systems that are around: many of the big brands have developed their own standards as we saw earlier.

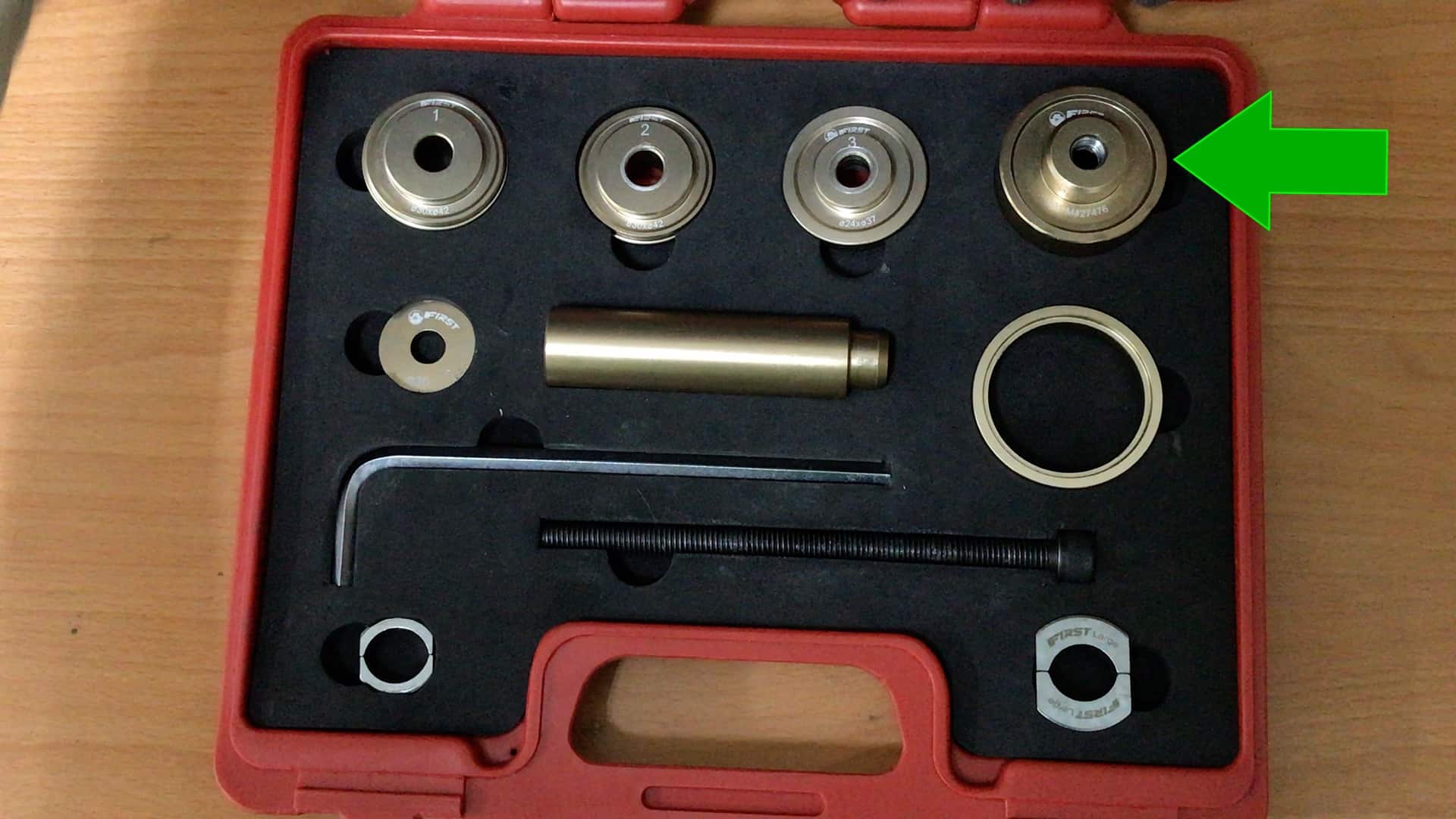

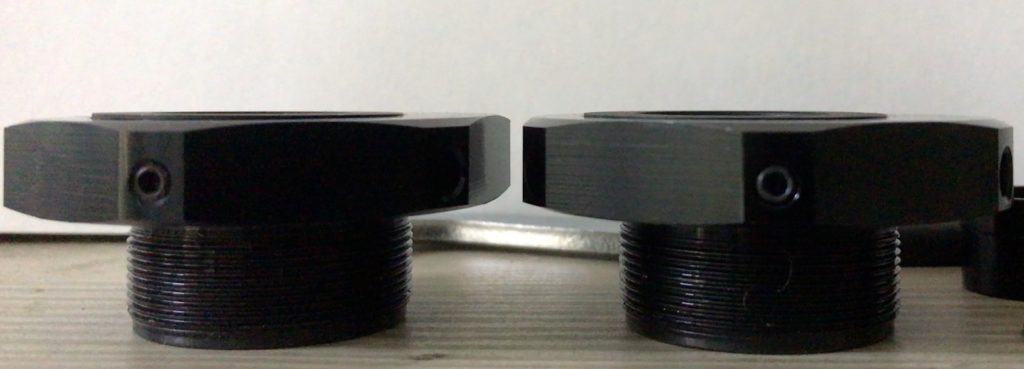

FIRST Components has designed several all-in-one toolsets for easy installation and removal of bearings and cups.

The BB2430 kit covers BB30 and BB86/92.

The pieces across the top row are for pressing in the 42mm ID 6806 bearings used for BB30 or the 41mm ID cups used in BB86/92.

The pieces on the far left and right at the bottom are for removing those same bearings or cups.

All other components support or hold those pieces in place during the installation or removal process.

The PF30 set also covers BB30 although the main emphasis is on PF30.

The idea is exactly the same including the way the pieces are used.

Unique MTB Bottom Bracket

MTB riders looking to super fine-tune their performance find advantage in being able to change the height or drop of their mtb’s bottom bracket.

Height is the distance of the center of the bottom bracket to the ground (assuming suspension is fully extended); drop is the distance from the center of the BB to the geometric line running from the front hub to the rear hub.

Which to use depends on personal preference—a higher BB allows greater maneuverability at low speeds and avoiding pedal strikes; a lower BB provides greater stability through corners at speed.

Height/drop can be quickly adjusted by installing an eccentric bottom bracket (EBB).

An EBB can be rotated around the BB’s central axis to any position.

In contrast to all other “concentric” bottom brackets its center is offset—rotating the unit moves the center either upwards/rearwards or forwards/downwards.

Having decided on a position, you fix that position by tightening small bolts laterally installed in the casing.

First’s unique EBB enables quick adjustment by using bolts installed longitudinally and permits adjustment to a maximum of 7mm.

Here’s how it works . . .

Installing an Eccentric MTB Bottom Bracket

All EBBs slide into the BB shell; tightening the bolts clamps the EBB’s cups to the shell.

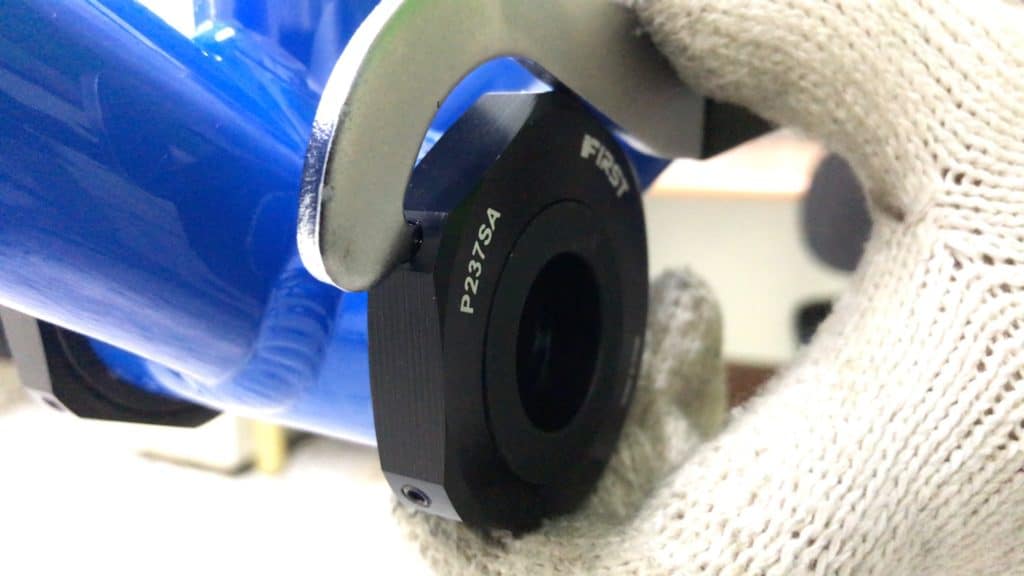

All except this one, which threads into a BSA threaded BB shell.

This design is enabled by locating the bearings in enlarged externally mounted casings and can be said to be an EBB version of an external bottom bracket.

It is easily installed by threading it into the shell as with any other external BB.

The difference lies in using the dedicated tool properly: the casing bolts must be tight otherwise the tool will rotate the casing and not the unit as a whole.

A generous greasing of the BB shell threads and EBB threads makes turning the unit by hand easy. Finish off by using the dedicated tool once the resistance becomes too stiff.

Insert the hook into one of the holes in the casing. Then lay the handle firmly against the edge of the casing to gain the leverage needed to tighten the cup.

The trick is to make sure the casing on each side is in the same position.

Installing the crank is impossible if each side is not concentrically aligned because one side will be higher or lower than the other.

Adjustment

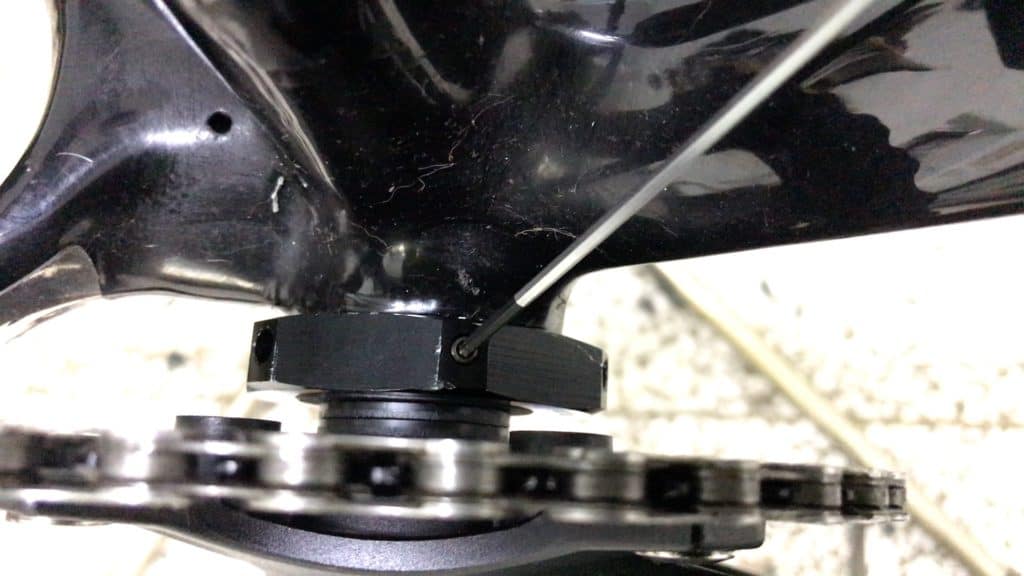

The whole idea behind this particular MTB bottom bracket design is to make adjustment easier.

Loosening each of the three bolts on the casing on each side is done with a 2mm Allen wrench.

You can then rotate each side bit-by-bit, a few millimeters at a time.

The quickest way is to rotate each side simultaneously, though, which means you have to get down low or put the bike up on a repair stand.

The key is to rotate each side in unison with the other to avoid one side getting out of alignment with the other—a mis-aligned spindle will jam which prevents further rotation.

THE LAST WORD

MTB bottom brackets will be around for a while yet—but possibly NOT for ever.

eMTBs overwhelmingly use mid-drive motors rather than hub drives.

Mid-drives install into a wide, open bracket connecting the down tube, seat tube, and chain stays.

It’s likely that traditional MTBs fitted with threaded or press fit BB setups will become the province of diehard riders who reject pedal assist or at least keep a traditional MTB around to be able to enjoy non-assist riding.

That won’t be soon. But with electrification fast becoming the standard, traditional MTB bottom brackets as described in this post may become a rarity sooner than later.