“Why are there so many bottom bracket standards?” is the question every single newcomer to the wonderful world of cycling has asked sooner or later.

(Even those of us who have been in the industry forever periodically ask ourselves the same question.)

The brief and cynical answer is that manufacturers focused on being different ultimately as a marketing/branding strategy.

Although the evidence in favor of that is very strong, there is a bit more to the story.

In this post I chart the evolution of bottom brackets from their simple, functional threaded beginnings through the whole press fit saga, up until the current return of threaded BBs in the form of T47.

CONTENTS

Threaded Bottom Bracket Standard

English Threaded

T47

Press Fit Bottom Bracket Standard

The BB30 Nightmare

The PF30 ‘Fix’

The Ultimate Answer—T47?

WHERE DID ALL THESE STANDARDS COME FROM?

Why has it got so complicated? Especially as the original “bicycle” didn’t have a bottom bracket because it didn’t have a crank.

Laufmachines & Higher Wheelers

The pedal bicycle’s precursor was the ‘running machine’, where the rider rested on what these days we call the top tube and pushed against the ground.

The major advance in bicycle design came with the High Wheeler or The Ordinary (you’ll probably know it as the Penny Farthing).

The cranks attached to the front wheel hub with the rider mounted directly above. The big wheel enabled gearing up in order to get enough speed—the bigger the wheel the higher the gear (but the more difficult pushing the crank).

Modern Safety Bike

Modern bottom bracket standards begin with the safety bike’s appearance from the mid 1880s. Why the safety bike? Because it was way, way safer than the High Wheeler.

You’ve probably heard of the term ‘Come a cropper’, right? It describes how a rider, perched precariously atop the huge front wheel is pitched forward over the handlebars onto the pavement whenever the front wheel dropped into a deep pothole or wedged in a crack.

Coming a cropper became much less of a problem with the safety bike’s front wheel being the same size as the back, made possible by an early version of the modern rear-wheel drivetrain:

- a centralized crank and chainwheel

- a chain

- a rear wheel sprocket

The centralized crank was made possible, of course, by the ubiquitous bearing assembly mounted at the lowest point of the twin diamond frame, known as the bottom bracket.

The question then became one of the relationship between form of the bearings and the frame.

The variety of answers to that simple question has given rise to the continually multiplying bottom bracket standards causing us headaches today.

The BSA Bottom Bracket

The easiest way to install bearings from the beginning was cup-bearings-cone installed into the frame with threads .

The Birmingham Small Arms company did not invent bottom brackets, but the name, BSA, has come to be associated with the most widely adopted standard, otherwise known as English threaded (so BSA bottom bracket and English threaded are interchangeable terms).

The drive side cup of this threaded bottom bracket has a left hand thread against the direction of rotation; the non-drive side has a conventional right hand thread that also threads against the rotational direction.

THE THREADED BOTTOM BRACKET STANDARD

A modern bottom bracket can be defined as a container for a set of bearings enabling a bike rider to turn the cranks.

Well actually, it’s a container within a container, the containing container being the bottom bracket shell—BB bearings are housed in cups or a cartridge which is then housed within the bottom bracket shell.

Frame manufacturers cut threads into the shell; bottom bracket manufacturers cut threads into a bearing cup’s outer diameter, allowing the cups or cartridge to be threaded into the bottom bracket shell.

English Threaded Bottom Bracket

English threaded BBs are the original bottom bracket standard; they dominate the low end and lower mid-range of bicycles these days.

An English threaded bearing cup’s outer diameter measures 1.37” or 34.8mm with 24 Threads Per Inch.

The bottom bracket shells into which threads are cut vary from 68mm in width (road bikes) to 73mm (mountain bikes); the shell’s inner diameter measures 34.8mm.

They almost universally appear in the form of cartridges (see below).

Italian Threaded

While English threaded BBs define the threaded bottom bracket standard (although see T47below), the Italian threaded standard is used on older bikes (Cinelli) and can still be found on Colnago threaded BBs today.

Italian threaded BBs don’t have a left hand thread and are therefore not technically equivalent to the English threaded standard.

The drive side bearing cup is a right-hand thread. Threading in the direction of crank rotation creates precession, where rotational force can loosen the cup.

The preventative solution is to use a torque wrench to ensure the cup is tightened to the recommended tolerance. Then periodical checking for looseness is a good idea.

Cartridges and Sealed Bearings

The most common threaded bottom bracket standard is BSA or English threaded.

A one-piece container—the “cartridge”—in which sealed bearings are mounted, replaces the old Cup and cone assembly.

Sealed bearings consist of ball bearings in a cage which is held in tension between an inner and outer race.

The side facing out is open and covered by a circular removable strip of nylon; the inner surface is closed at the back.

Removing the circular strip allows you to clean and re-grease the bearings.

The bearing cage is not meant to be disassembled, though (Shimano warn against disassembly on all their threaded bottom brackets).

Sealed bearings are designed to be replaced as a whole on a range of other bottom bracket units except cartridge bearings.

Sealed bearings snug around a square taper spindle that runs through the unit. The bearing, spindle and threaded sleeve are pressed into position during manufacture.

The cartridge is threaded into the drive side. A lock ring independently threads into the bottom bracket shell on the non-drive side.

Cartridges — Pros and Cons

Cartridge sealed bearings’ ball bearings are small. Since small bearings are not as durable as larger bearings, they wear out more easily.

The telltale sign of wear is creaking under load.

You might think that the cartridge’s sealed bearings will be easier to replace than loose bearings. But no.

The sealed bearing units are pressed into the cartridge casing with considerable force during manufacture—there’s no easy way to replace them.

The best way to go (and the good thing about cartridge bottom brackets) is to replace the whole cartridge. They’re cheap, easy to install, and easy to remove with a few readily available tools.

Check out the video for everything you need to know about cartridge bottom bracket installation and removal

Single Piece Crank

You’ll find single piece cranks on entry-level road bikes, mostly at big-box stores.

Cups pressed into the BB shell act as the bearing race. The ball bearings are contained in a cage and held in place by a cone and lock ring.

T47

The T47 bottom bracket standard represents a return to threaded (T=“threaded”) bottom brackets in reaction to the dominant press fit design (the next section is devoted to press fit).

T47 was introduced to mixed opinions in 2015. “That’s just what we need! Sheesh!!”, was one predictable reaction from the cycling world.

The reception was generally warm, however, and by the 2020 product year, the T47 had received broad-based acceptance.

T47 takes up where the PF30 bottom bracket standard leaves off: the story of T47 is the story of the nearly two decade-long press fit bottom bracket standard saga.

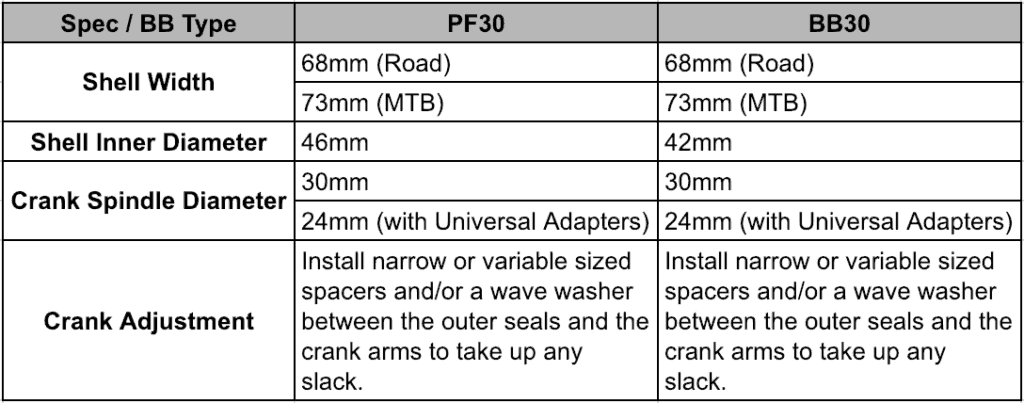

Briefly, press fit BB standards saw bottom bracket shells increase in size from 34.8mm to 42/41mm, and then to 46mm—T47 is basically a threaded 46mm bb shell. We’ll return to that below in talking about PF30.

T47 installation and removal video

THE PRESS FIT BOTTOM BRACKET STANDARD

Once upon a time you installed a bike’s headset by pressing cups into the head tube’s top and bottom.

The bearings initially installed loosely into this race; later they were contained in a cage.

With the advent of sealed bearings, the next step was to do away with the cups. A shallow ‘lip’ integrated into the top and bottom of the head tube, provided a seat for a sealed bearing unit. Voilà…the integrated headset is born.

Now, if you could do that for the head tube, why not for the bottom bracket shell. Why not do away with the soooo 19th century threads, and place bearings directly into the BB shell?

Even better was the weight reduction, since you did away with the bearings’ supporting cups as well.

Pressing the bearings directly into the bottom bracket shell gave the cycling world the press fit bottom bracket.

Cannondale’s BB30

In design terms, Cannondale’s BB 30 bottom bracket standard was the first adaption of the integrated headset idea to bottom brackets.

The driving force behind this new design, however, was the quest to install a crank with a 30mm spindle, replacing the ubiquitous 24mm spindle—hence the “30” in BB30.

The larger diameter spindle used a sealed bearing with an inner diameter (ID) of 30mm; the outer diameter (OD) was 42mm requiring a much larger BB shell with a corresponding ID of 42mm.

The larger diameter firstly provides a lighter integrated spindle.

The move from steel to lighter aluminum in bike frame tubing design uses the same principle. Aluminum is much lighter and not as strong. But using larger tubing (and elongated tubing for the down tube) overcomes the strength disadvantage.

Equally important, a 30mm spindle is stiffer than a 24mm spindle due to the larger diameter.

In sum, the BB30 innovation promised a boost in performance by reducing weight (and Q-factor into the bargain) whist also increasing stiffness.

BB30 Nightmares

The BB30 bottom bracket standard was quickly adopted, but also quickly attracted criticism.

Installing the 6806 sealed bearings into the BB shell requires skill and the right tools. The bearings must be seated exactly in the right position, the C-clips squared against the internal lip and against the C-clips.

Even if installed correctly the forces acting on the bearings within the bottom bracket shell are immense, way beyond any exerted on integrated headsets for example, which is why translating the integrated headset concept to the bottom bracket was guaranteed to have problems.

The most common complaint was bottom bracket creak due to flex and movement around the bottom bracket shell and the bearings against the shell.

A threaded bottom bracket’s threads lock together allowing only a tiny degree of movement—assuming the bearing cups are tightened to the correct torque of course.

Provided the install is carried out correctly, there’ll be no noise for many moons. Eventually you the creaking comes, signaling that the cartridge’s sealed bearings are nearing the end and it’s time to replace the cartridge.

Shimano and SRAM’s Reply

The answers to the BB30 ‘innovation’ focused on getting those bearings away from the bottom bracket shell and back into housings.

First Shimano and then SRAM came up with their own press fit alternatives.

BB86/BB92

Shimano’s design reduced the BB shell ID by 1mm to 41mm and placed the sealed bearings inside cups

But this brought the bearings “inboard”again. With the move to integrated 24mm spindle cranks, sealed bearings were relocated out of the BB shell to accommodate Hollowtech’s increased spindle diameter.

FIRST’s toolkit for BB86/92 installation and removal

Trek’s BB90

The Trek design was a combination of the traditional BB30 and the Shimano cups. Trek built the sealed bearing housing or ‘cups’ into the BB shell itself into which the sealed bearings were installed.

PF30

During the 2010 Taipei Cycle show, a Shimano rep strolled around the myriad First Floor smaller component brands and bike brands booths asking the question of many: “Why haven’t you changed over to press fit yet?” From a manufacturer’s point of view, press fit was superior and must be a winner with consumers.

However, the answer was:

- Users complained about the creaking

- For dealers, threaded worked just fine anyway

In 2009, SRAM introduced their solution to BB30’s technical woes. They increased the BB shell internal diameter by 4mm to 46mm.

The increased shell size was welcome. The main problem, though, was a wide variation in manufacturing tolerances.

The differences amongst manufacturers ensured that there were plenty of mis-matches between particular frames and particular PF30 cups. Hence, once again many cyclists had cause to complain about incurably creaky bottom bracket setups.

Now, the whole concept of PF30 is a good one. You’ve got large bottom bracket shell enabling the installation of larger bearings and giving leeway over crank choice as well.

Thus, one sunny day in 2014, Chris King turned to Ben Farver of Argonaut Cycles (or maybe it was the other way around…) and asked the question: “What if we cut threads into the shell and installed a threaded cup instead, doing away with this darned press fit business altogether?”…

FIRST’s toolkit for removing or installing PF30 BBs

…T47—Revisited

And that brings us back to T47 which in hindsight makes the whole press fit episode appear as a haphazard evolution from English threaded and their smaller bearings through to T47 which allows much larger bearings.

In the summer of 2020, when the world was sinking deeper into the mother of all pandemics, Specialized released their S-Works Tarmac SL7 2021 and Trek, their Emonda SLR and SL.

And as a sign of where things are going, Trek also plans to make use of T47 in many other models in their road range in the future.

You can also expect T47 to become widely adopted in e-bike mid drive motors in the near future. Given the stresses increasingly powerful motors exert on components, robust bottom bracket/crank setups promise low-maintenance and possibly troublefree.

Imagine that? T47 could become the mother of all bottom bracket standards given the explosion of e-bikes as clearly the future of both mass cycling including its various niche expressions.

FINAL THOUGHTS

Original BSA along with modern press fit models will be around for a long time yet.

The question now, though, is “Have press fit bottom brackets had their day”? With Specialized and Trek’s introduction of T47 into their ranges, will we see 2021 as the year in which threaded bottom brackets returned to standardize and simplify a component that has become unnecessarily complicated?

Let me know what you think…

1 Kommentar zu „Bottom Bracket Standards from Threaded to Press Fit (& more)“

my spindle has HDL written on it; what does it mean🤔