The BB86 bottom bracket standard is one of the mostly widely used press fit bottom brackets.

You’ll find all the answers to the following questions and more in this review of the BB86 standard:

- How BB86 differs from other press fit standards

- What frames they fit

- What cranks fit them

- How to install and remove BB86 cups—without damaging them

CONTENTS

What is BB86?

BB86 vs BB92 vs BB30

What is a BB86 Frame?

What Cranks Fit BB86?

BB86 Removal

Impact Removal

Non-impact Removal

BB86 Installation

BB86 Bottom Brackets from First Components

WHAT IS BB86?

BB86 is a later generation of press fit bottom bracket that enabled cyclists who were happy with standard 24mm diameter integrated cranks to continue to use them.

Let me explain: the development of press fit began with BB30’s 42mm non-threaded BB shell.

Shells were originally overwhelmingly produced in the English threaded standard of 34.8mm.

Enlarging them from 34.8mm to 42mm made it possible to expand the diameter of the crank spindle from 24mm to 30mm thus creating stiffer and lighter cranks.

The BB86 standard was introduced by Shimano and reduced the shell diameter by 1mm to 41mm. BB86 bottom brackets accepted standard 24mm integrated cranks.

The “86” refers to the width of the bottom bracket that fits into a standard road bike. 86 is shorthand as the exact width is is 86.5mm.

BB86 vs BB92 vs BB30

BB86 becomes BB”92” when pressed into a mountain bike frame—MTB frames manufactured to this standard are 91.5mm in width across the BB shell.

The difference is that the internal plastic sleeve is longer on a 91.5mm unit. Although most units are installed with sleeves they’re not mandatory as we will see below.

A BB30 bottom bracket is the odd one out here due to the 42mm outer diameter and 30mm internal diameter in order to accommodate the 30mm diameter spindle.

The shell width is standard, however: 68mm for road bikes; 73mm for mountain bikes.

WHAT IS A BB86 FRAME?

It’s not a mountain bike frame which has a 91.5mm wide shell.

It’s a road bike frame with a 86.5mm wide shell that accepts BB86 bottom bracket cups .

In the days when BSA 34.8mm bottom brackets ruled, and even with the arrival of press fit in the form of BB30, the BB shell was 68mm.

A BB86 frame increases the shell width by a significant 18mm which creates a beefier, less flexible and more efficient bottom bracket which is especially important in enhancing the stiffness of carbon frames.

Compare the thin tubes in carbon frames from the early 2000s, when carbon began to supersede aluminum, with the bulked up frames of the later 2000s characterized by oversized down tubes that meld into generously endowed bottom brackets and a very, VERY stiff frames.

WHAT CRANKS FIT BB86?

Integrated cranks with a 24mm spindle—you won’t be using a 30mm spindle with the BB86 press fit setup . . . which is the whole point.

BB86 allows cyclists who either don’t need, or don’t want to use, a 30mm crank to keep on using 24mm.

BB86 REMOVAL

BB86 press fit cups are held inside the 41mm diameter shell by the force of the surface of the cup against the surface of the shell.

That means forcing the cups in; and then forcing them out. Shell manufacturers and cup manufacturers manage to produce their respective components within acceptable tolerances—cups usually fit into shells tightly, without being impossibly tight.

If you’re replacing a pair of BB86 cups—two cups and their connecting sleeve (where used) make up a BB86 BB—due to noise, the cause of that noise may well be a possible shape differential.

Shell manufacturing tolerances can vary widely unlike cup manufacturing where the bearing cups are machined to 100% concentricity for practical purposes.

Shells are more likely to be eccentric so the difference in alignment with an almost perfectly concentric cup will likely result in movement under the stress of pedaling which may well be the source of any creaking or squeaking.

Getting a BB86 Cup Out of the Shell via Impact Removal

One popular tool for removing BB86 is an impact driver of some sort.

These are blunt at one end, flared at the other. The blunt end inserts into the shell through the cup you wish to extract.

The flared end contracts as you push it into the cup and BB shell, then snaps out into position inside the cup. Hitting the blunt end with a hammer a few times will force the cup out of the shell.

This one is at the extreme end of these impact models.

The wedges on the end are held in place by a rubber ring and generally hold their position under impact.

However they can also easily dislodge whereupon you have to remove it and try again.

This is the type you’ll more commonly find in toolkits, a practical and more easy to use design.

There are two potential problems with this removal solution. Damage to the cup from:

1 from the tool during removal

2 from being ejected and striking a hard surface

1. During Removal

The flared end of the tool jams against the inside of the cup.

Given that a cup is secured firmly in the shell, several blows are required to move the cup to the point where it’s ready to release from the shell.

In the case of a nylon cup, the likelihood of damaging the casing holding the sealed bearings is high.

It does not matter so much for alloy cups although those that stubbornly resist removal will likely sustain some damage.

2. Damage from Ejection

If a cup is secured really tightly in the shell it’s going to pop out with a lot of energy at the point of release.

You need to prevent it from dropping on the floor or slamming into a hard object when it launches from the shell—as launch it probably will

Nylon will be more likely to crack. Alloy may dent and the impact may also damage the sealed bearing.

No Impact Removal

The best way to remove a BB86 press fit cup is through the application of gentle pressure removing a cup little-by-little to the point where the cup drops into the tool’s container.

The following is a compact description of this process.

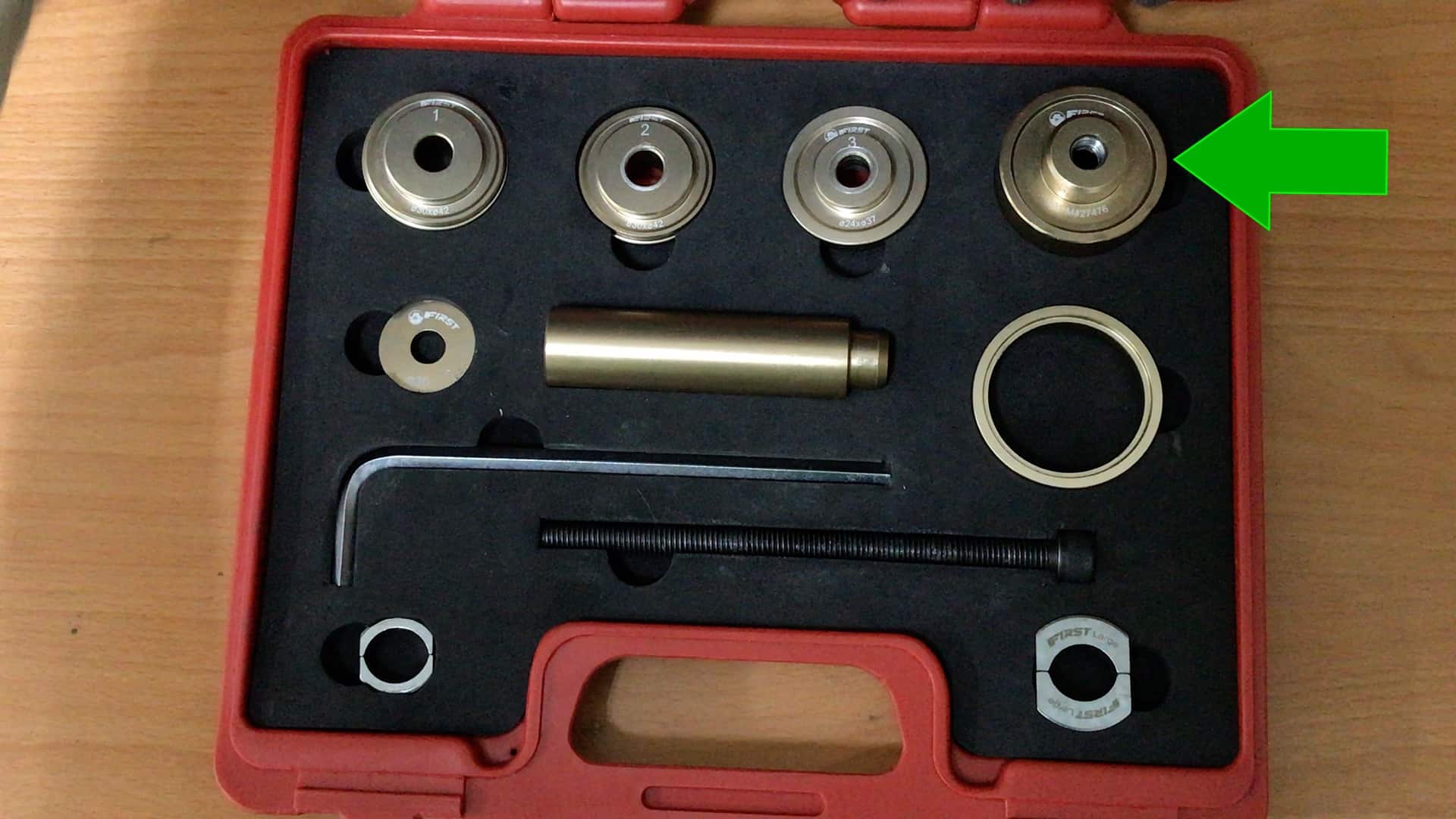

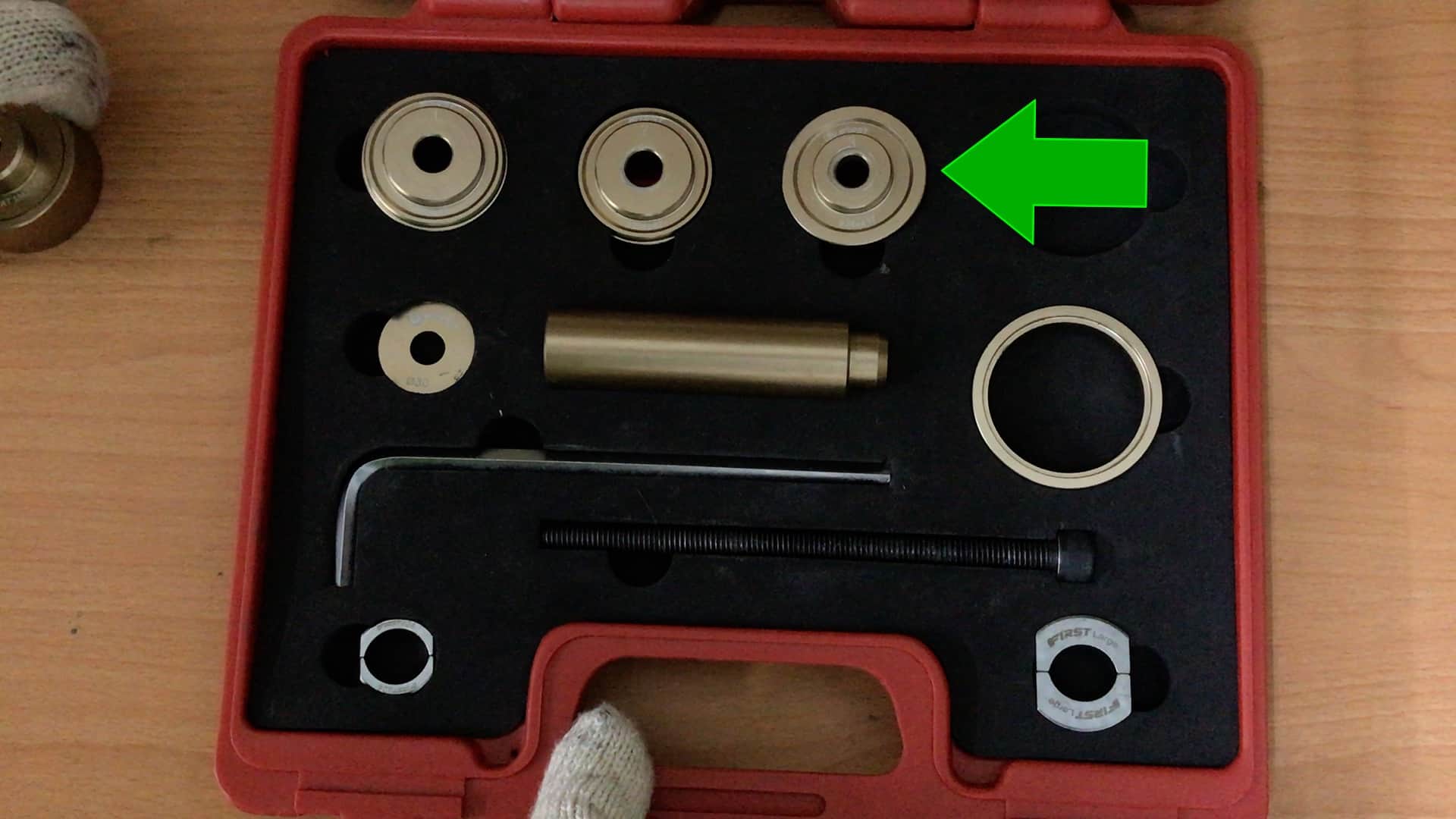

The BB2430 removal and installation kit for press fit BBs with either 24mm or 30mm spindles (excluding PF30 which is covered by the DF30 tool) makes the job easy.

The arrow in the image points to the cup that is pivotal in the removal, the receptacle that contains a cup once it moves free of the BB shell.

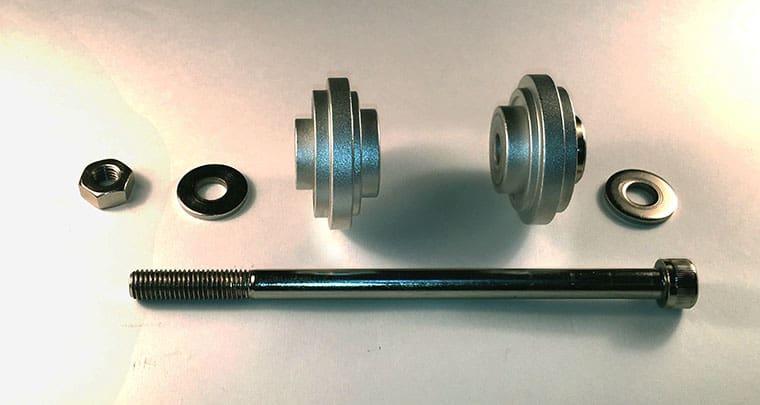

The key pieces:

Rear—the mounting shaft for the split steel-hitch, the steel-hitch

Front Row—Allen wrench, Nut/Receptacle, Retaining Ring for Nut, Main Bolt

The bolt is passed through the mounting shaft with the split steel-hitch and then passed through the bottom bracket.

The nut/receptacle threads onto the bolt; tightening the bolt provides the resistance for the mounting shaft and steel-hitch to complete the extraction.

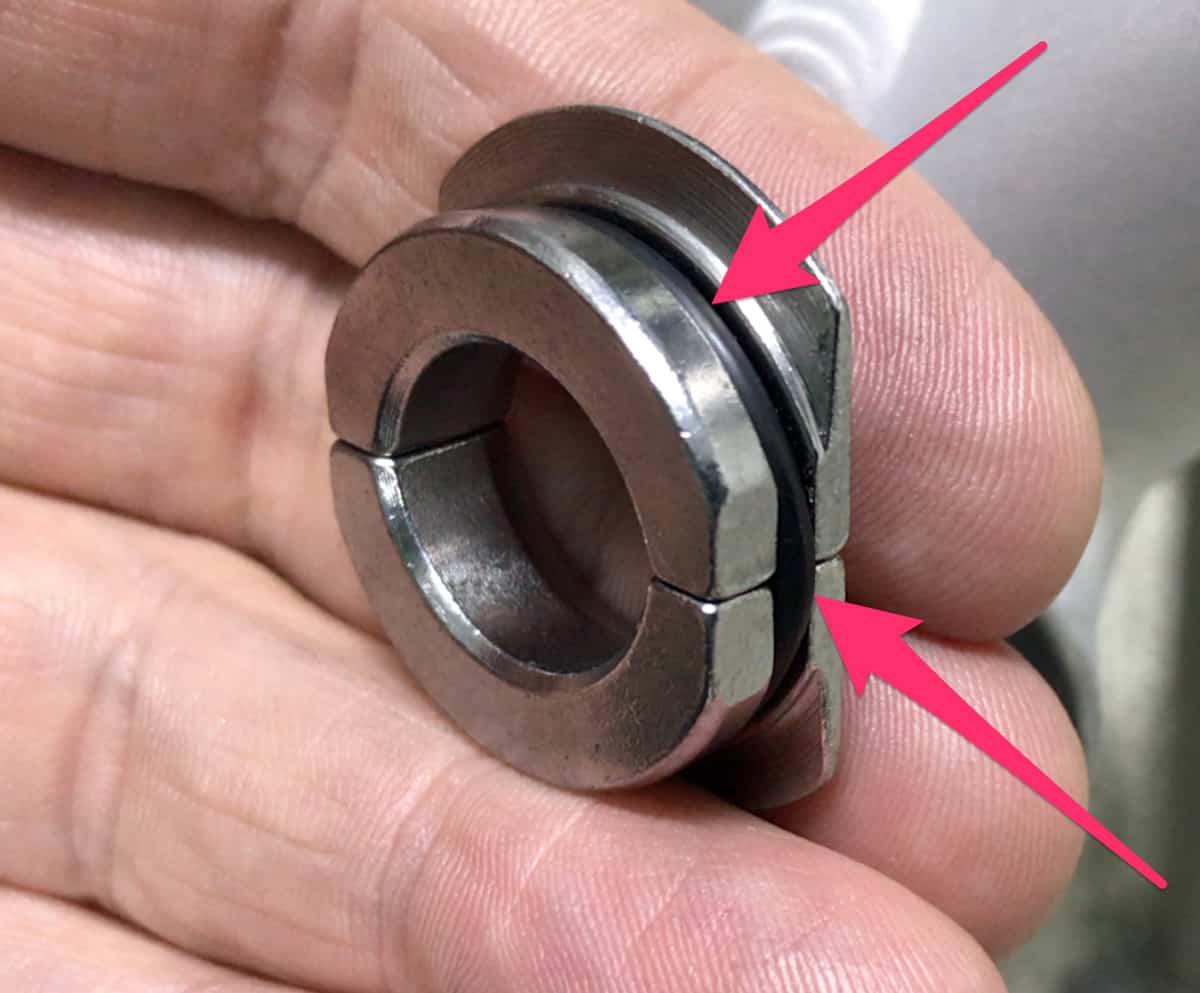

The split steel-hitch is the removable bracket which anchors against the interior edge of a BB86 cup.

Both halves fit into each other and are held together by an elastic rubber ring which expands onto the end of the mounting shaft.

That’s ready to fit into a BB86 bottom bracket and the way to get it into position is by firstly inserting the shaft without the steel-hitch.

You insert the steel-hitch sideways into the BB and then over the end of the shaft inside the BB shell.

The steel-hitch expands over the shaft as you simultaneously push it into the BB86’s internal diameter.

Then insert the bolt from the other side into the rear of the shaft.

Screw the receptacle/nut onto the bolt—the retaining ring may be necessary (as in this case) depending on the type of frame.

Then it’s a matter of turning the bolt which, bracing against the receptacle/nut on the opposite side, gently forces the steel-hitch against the BB86’s edge which in turn presses it out of the BB shell.

Once a BB86 cup is pressed out of the shell, it rests in the receptacle.

You then slide the bolt with the three pieces out of the BB shell, retrieve the freshly removed cup, then repeat for the other side.

BB86 INSTALLATION

If applying gentle pressure is the best way to remove a cup, then that’s also the best way to install it.

There are plenty of variations of this simple tool around online. Or you can make your own (check out “DIY press fit tools” on YouTube).

But since BB86 removal is the more difficult operation, by far, and where you need to remove you also need to install, it’s best to have a tool that can do both, such as the BB2430 kit.

The pieces you need are the 24mm disk (green arrow), the bolt, and the receptacle/nut which is used in reverse for installing a BB86 cup (as opposed to removing a cup).

The bolt inserts through the disk which will carry the burden of pressing in the BB86 cup.

Lodging an appropriately greased cup just inside the lip of the BB shell, slide the bolt in and the disk will slot into, and against, the cup.

Thread the retainer onto the bolt—the convex end fits into the BB shell, the opposite of the removal process.

Cranking the bolt with the Allen wrench presses the BB cup into the shell.

Releasing the bolt by undoing the receptacle then repeating the operation for the other side gives you a fully installed BB86 bottom bracket.

With a little practice the whole process takes less than a few minutes.

BB86 BOTTOM BRACKETS BY FIRST COMPONENTS

Here are some examples of FIRST Components’ BB86 units from the higher end to the lower end (only available for OEM/ODM customers).

If weight was a concern these minimalist 41mm cups with ceramic bearings weigh in at around 64g—around 70g with a standard sealed bearing. T86 for Shimano; R86 for SRAM.

The G92S threaded sleeve means installation and removal with the one wrench—a 16T wrench does the trick. This one’s for Shimano; the G92R version is for SRAM.

At 110g it’s heavier, of course.

This is the unit as it would appear installed in the BB shell.

The R92S (R92R for SRAM) weights 92g with alloy cups and a clear sleeve which requires all the tools for installation and removal.

The H92S (Shimano; H92R for SRAM) weighs 77g.

Since it’s nylon, extra care must be taken on removal, especially with an impact removal tool. It’s very easy to crack the nylon casing where cups are tightly fitted into the BB shell. All the more reason to use non-impact methods.

MORE INFORMATION

You might find the companion article focusing on BB92 to give you extra insight into the issues surrounding this popular road bike press fit bottom bracket.