The bottom bracket shell on a modern bike is the container into which the bottom bracket is pressed or threaded.

Keep reading as we take a detailed look at this humble, yet key, piece of the geometric balancing act that is the modern bike frame.

CONTENTS

- The 9 Tubes Making Up a Bike Frame

- Types of Bottom Bracket Shell

- Bottom Bracket Shell Modification – Adapters

- The E-bike Influence on Bottom Bracket Shells

The bottom bracket shell is one of the nine essential building blocks of every bike frame, although, in the beginning, tubes were not that numerous.

Standard bike design dates from the mid 1880s which replaced the single curve of The Ordinary (Penny Farthing) with the twin triangles of Starley’s safety bike, the ‘Rover’

The Ordinary lacked a bottom bracket since the pedals were a part of the hub.

The appearance of the Rover in 1885, gave us the design from which we have rarely deviated (while noting the lack of a seat tube in the Rover).

THE 9 TUBES OF A BIKE FRAME

- Head tube

- Bottom bracket shell

- Top tube

- Down tube

- Seat tube

- Chain stays (x2)

- Seat stays (x2)

The characteristic way to look at modern bike geometry is as a pair of triangles which share one side, the seat tube.

You can also view a bike in terms of two levels, upper and lower with reference to the bottom bracket shell.

Top tube and head tube define the upper level; all other tubes define the lower level since they all connect to the bottom bracket shell.

The bottom bracket shell functions as the frame’s primary foundation or support.

The down tube and seat tube bear directly down on it, supporting the head tube at one end and most of the rider’s weight at the other.

Although modern frame designers (particularly of urban, lightweight and folding bikes as you’ll commonly see in Taipei Cycle’s International Bicycle Design Competition) try hard to move beyond the twin triangle, it still dominates—function still prevails over form.

And the bottom bracket shell remains a crucial component.

TYPES OF BOTTOM BRACKET SHELL

There are two types: threaded and press fit.

Threaded shells and threaded bottom brackets dominated frame design until the arrival of the simultaneous — although unrelated — innovations of carbon frames and press fit bottom brackets in the 2000s.

Threaded

Threaded alloy bottom bracket shells were the only shells for decades.

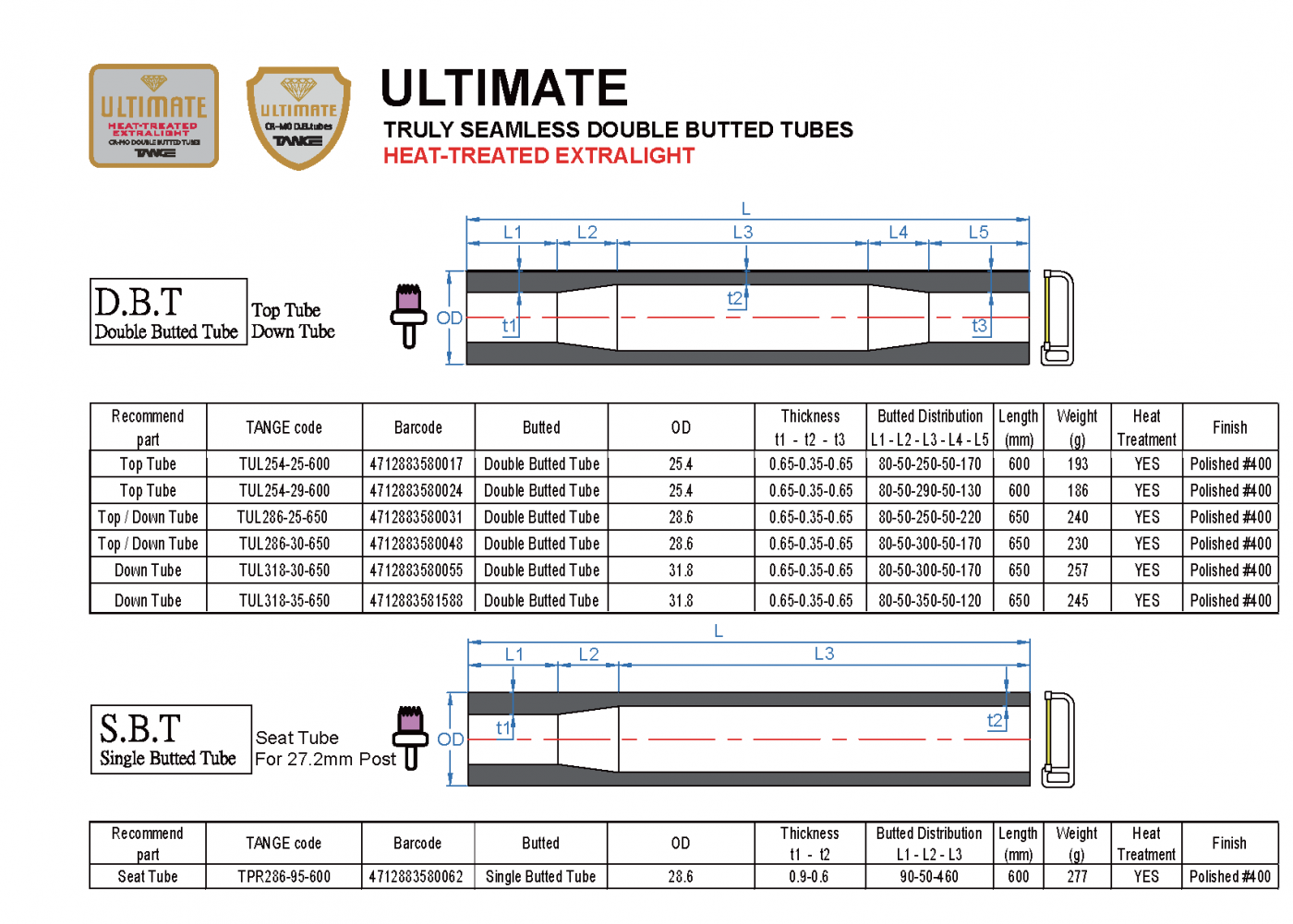

In the supply chain threaded BB shells start out as just another tube produced by a tubing company.

It may be offered by a tubing manufacturer which covers a range of tubes.

More likely a specialized manufacturer such as Taiwan’s Hsiang Huang supply tubing companies further downstream.

Hsiang Huang, for example, is a classically traditional workshop, one of thousands making up Taiwan’s bicycle component manufacturing sector, which does business via phone or fax . . . no website or email.

They specialize in head tubes, front fork stems, and bottom bracket shells along with an assortment of frame extension and enhancement bits and pieces.

The bottom bracket shell variables are length, OD, and ID.

A frame manufacturer can order a standard 68mm, 73mm, or 100/120mm version for a fat bike for example.

Or they can produce a custom order anywhere between 60mm – 132mm which covers every conceivable design scenario.

OD possibilities lie within a 30-62mm range with the ID range beginning with the classic BSA shell internal diameter of 34mm (34.8 precisely) and covering press fit 41, 42, 46mm, on up to American BB 51mm and eccentric BB models with 54.5mm IDs.

The holes in the shells are placed where the other tubes are welded to it—the edges are welded into each other together with the TIG filler rod.

Head tubes are prepared in the same way.

Who Cuts the Threads?

A factory such as Hsiang Huang supplies a smooth bottom bracket shell, unthreaded.

An alloy or steel frame factory spot welds the nine tubes into place, or receives them from the contracting supplier already spot welded.

The frame is then TIG welded, sent out consecutively for T4 (weld strengthening heat treatment) and T6 (frame strengthening) treatment.

Frame factories also outsource the cutting of threads into the bottom bracket shell.

Carbon Frames – Alloy Inserts & Stiffness Issues

Carbon enables lightweight, strong frames and allows manufacturers to create almost any shape that can be imagined.

Carbon fiber frames are strong, but flex more than steel and alloy, especially at the bottom bracket which is subject to highest torsional stress.

The ability to mold carbon fiber layers and increase the number of layers where required saw the inclusion of massively reinforced bottom bracket shells on carbon frames.

Several disadvantages accompany these benefits however.

Cutting threads into carbon is possible but most manufacturers opt to fit a threaded alloy sleeve into the bottom bracket shell.

Glueing alloy to carbon quickly matured when fitting carbon seat stays to alloy frames was a thing in the late 2000s (along with glueing carbon fork blades to alloy crowns and steerers).

Alloy inserts fitted in this way reliably remain in place; problems that occur generally concern tolerance discrepancies between the shape of the insert and the bottom bracket (see next section).

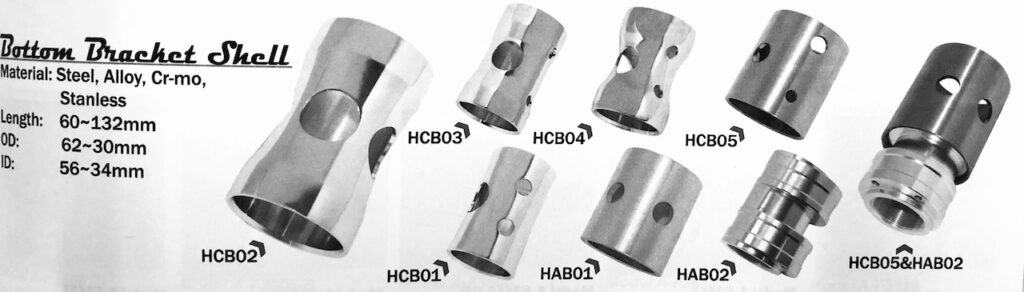

Press Fit Bottom Bracket Shells

Getting rid of threads and pressing bearings or bearing cups directly into a bottom bracket shell made sense at the time.

PF BB shells don’t require threads to be cut into them. All you need is the right tool or technique to install them (trickier to remove though…).

A key characteristic of this type of bottom bracket shell is the interior lip which catches the edge of the bearing cup (or the sealed bearing itself in the case of BB30)

But for every lover of press fit designs there is also a critic . . . and perhaps the critics outnumber the satisfied users by now.

The Problem of Mismatched Bottom Bracket Shells and Bottom Brackets

Complaints about noisy press fit bottom brackets began soon after the introduction of BB30.

The thing is bottom bracket shells and bottom brackets are manufactured to different shape tolerances.

In a perfect world bottom bracket shells are perfectly round with zero elongation; the same with bottom bracket cups.

But bottom bracket shells are never free from some degree of elongation.

T4 and T6 heat treatments of alloy frames are a significant cause of frame and tubing warping, and all frames require fitting into a jig for straightening.

Most frame makers don’t allow for more than 3mm of deviation from square.

Imperfectly shaped, threaded bottom bracket shells don’t matter since the greater variable in play is the cut of the threads, as long as they are not too far out of whack of course.

Provided the bearing cups are greased and tightened to tolerance, they’ll be noise-free until the ball bearings wear out.

Press fit cups are a different story

The tight bond established between bottom bracket shell threads and BB cups or a BB cartridge is not established in the fit between press-in cups and a smooth shell.

That’s why conscientious bike builders tap the threads prior to installing a cartridge or cups.

Factories cut the bottom bracket shell threads cleanly 99 times out of 100, and a tapping session rarely removes any material anyway, although the check should always be carried out before BB installation.

Tapping the shell threads ensures they are perfectly aligned with the BB cup or cartridge threads.

The most common problem is if the fit is too tight which is the common sign of a cross-threaded bottom bracket.

Tapping the shell eliminates the tight fit, or rather, prevents it in the first place. If a BB cup or cartridge is still almost too tight to install, then the bike builder is probably dealing with a cross threaded BB.

With a press fit BB, 99 times out of 100 you’ll be faced with slight differences between the shape of the bearing cup and the bottom bracket shell.

A perfectly round bottom bracket shell and perfectly round BB cup surface will fit together—perfectly.

Different shapes means an unequal distribution of contact between both surfaces resulting in a greater likelihood of movement under stress as the bike is being ridden.

Movement happens more often than not and is the source of the creaking so many press fit BB users complain about.

BOTTOM BRACKET SHELL ADAPTORS

One way of getting around noisy press fit BBs has been to replace a noisy press fit with a threaded model.

This is done by in, essence, replacing the bottom bracket shell.

Pressing in the right adapter to fit a 41, 42, or 46mm bottom bracket shell allows the fitting of 34.8mm (“BSA”) cups or cartridge.

Or a 41mm press fit sleeve if you wanted to avoid a BSA solution.

FIRST offers the following adapters:

- a simple press-in cup (lightest)

- press-in cups with attached sleeves

- cups and sleeve with expanding friction bands (heaviest but easiest)

Note that these are for bike brands or shops looking to manufacture by the batch and are not available directly to consumers. Products available to cyclists are listed on this page.

Converting a press fit bottom bracket to a threaded bottom bracket (or 41mm) means using a 24mm spindle crank.

Since press fit bottom bracket shell sizes are 41, 42, and 46mm respectively, the goal is to identify the adapter sleeve that fits.

Install the cups and S30 (with sleeve) or the S30 solution with a press fit tooluse the S30 solution; or the g207A model with the friction bands.

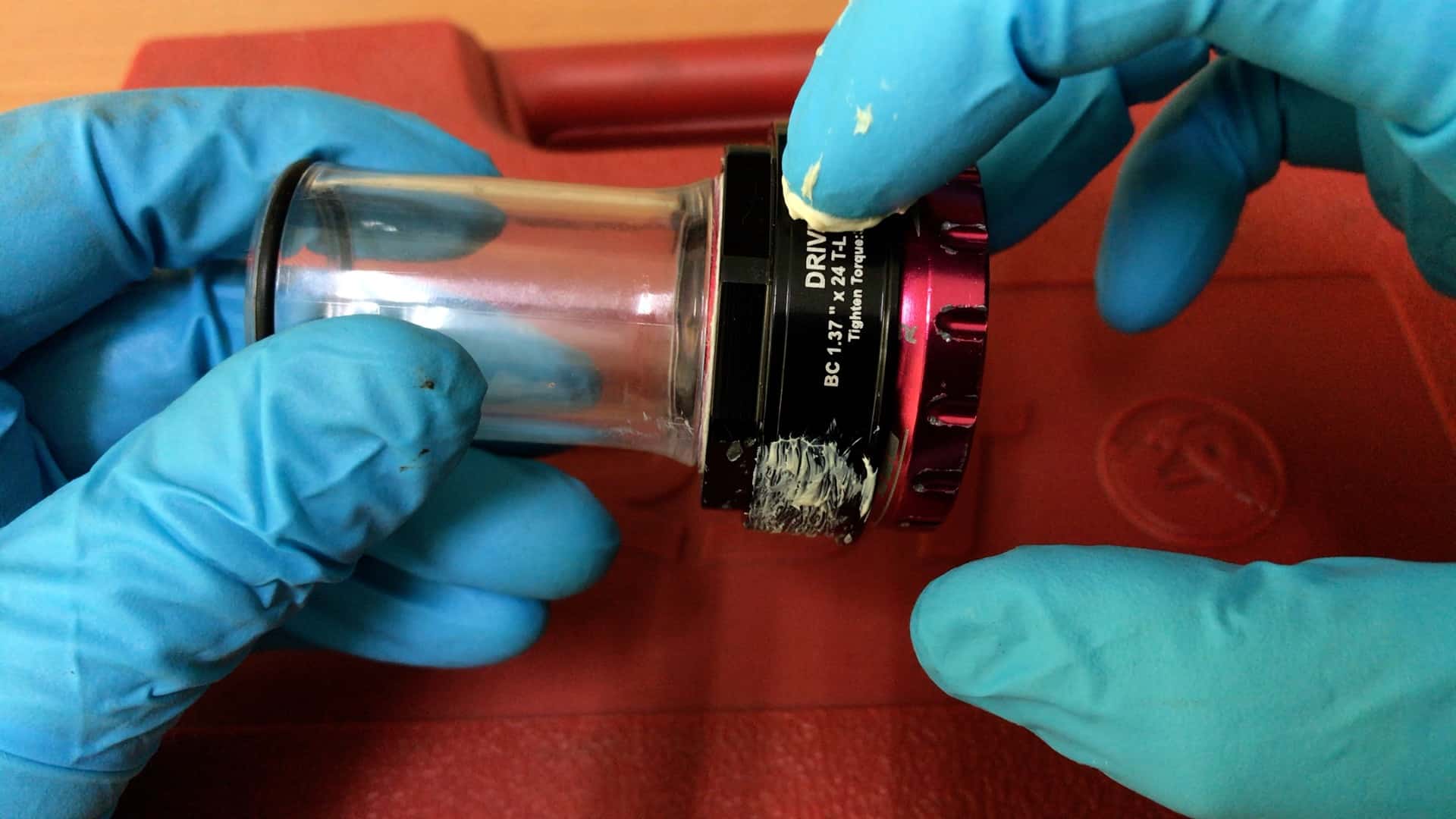

Installing the Cups

The minimalist adapter solution is to install individual cups.

Best to thread the BSA bottom bracket into the cup before pressing it into the bottom bracket shell.

Then tighten each cup to torque tolerance using a vice and a torque wrench that can handle 50Nm (35Nm minimum for this model).

You prepare the cups for installation as you would any press fit cup by applying a good coat of grease.

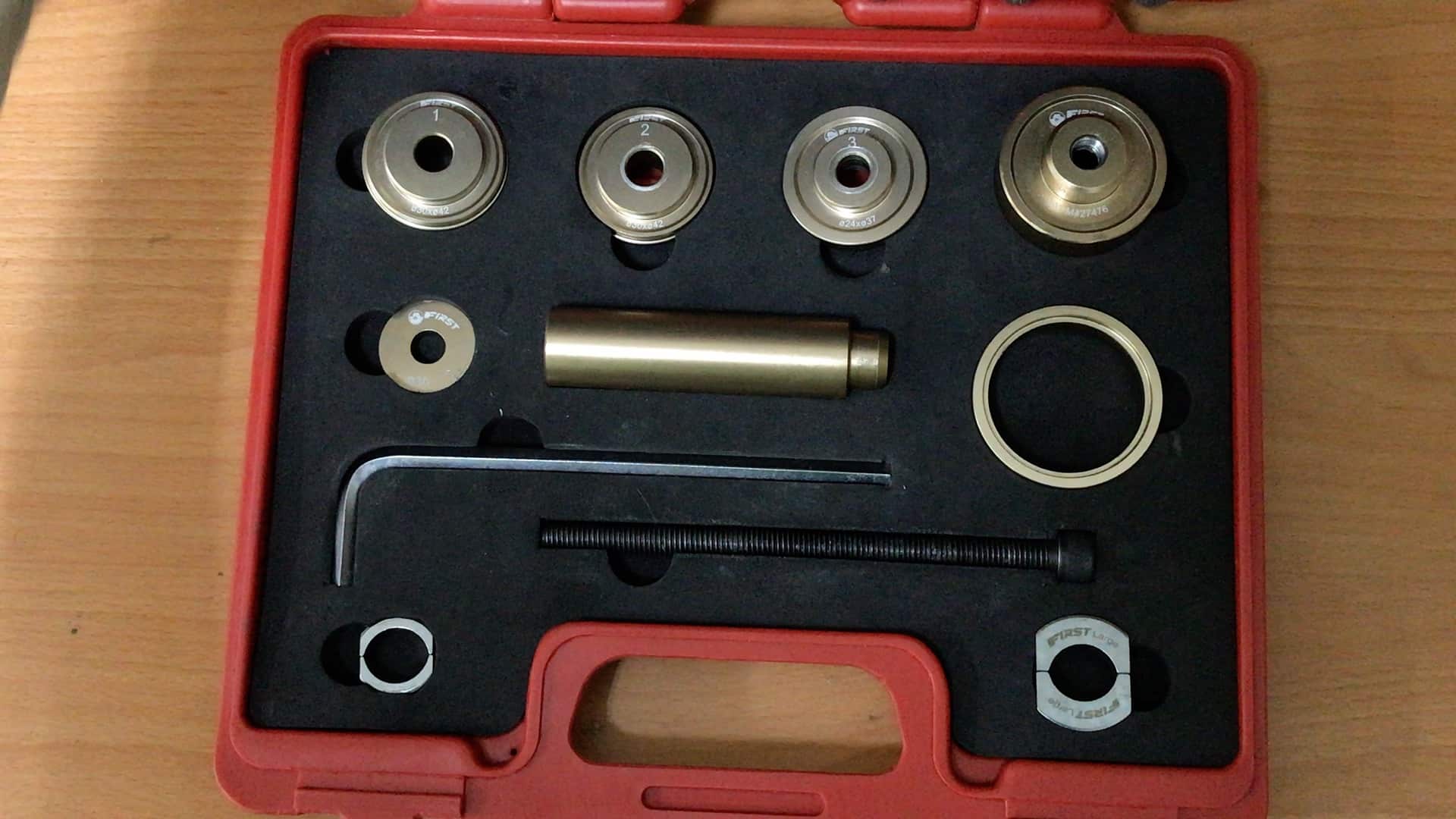

A press fit BB tool like FIRST’s BB2430 kit allows easy fitting . . . and removal.

You can also install each cup using a home-made press—two disks and a long bolt with matching nuts will do.

Using a toolkit makes it easier, though, and you will be able to remove the cups with no risk of damage to the cups or the frame (ie. you won’t have to use an impact tool).

Single Unit With Expansion Bands

The simplest solution is an adapter that uses expansion bands.

No need for grease with this model, which converts a 46mm PF30 bottom bracket shell to a threaded 34.8mm shell.

Slide the unit into the bottom bracket shell.

Then tighten each of the 3mm bolts a turn or two at a time in succession.

The corrugated bands grip the BB shell as firmly as if you’d threaded them in.

There is now a threaded 46mm shell, the T47 standard. And although you are technically able to cut threads in a 46mm shell in order to fit a T47 BB, it’s a tricky business and not advisable.

Having secured the bolts, thread the BB in as you would with any threaded bottom bracket shell. Then tighten to tolerance.

THE INFLUENCE E-BIKE FRAME DESIGN ON BOTTOM BRACKET SHELLS

Two things have happened to bottom bracket shells with the mass transition to e-bikes that began in 2016 and accelerated in 2020 due to Covid 19 effects: extensive modification and simplification.

Extensive Modification

E-bikes are powered by a mid-drive motor or a hub drive.

Installing a mid-drive motor eliminates the bottom bracket and therefore the bottom bracket shell . . . as we know it.

The motor bolts directly into the junction of the down tube, seat tube, chain and seat stays.

In a conventional bike, each tube is welded to the bottom bracket shell.

An e-bike mid-drive frame has the structural problem of securing those tubes over the greatly expanded surface of the bracket to which the motor is bolted.

Functionally, you still have a bottom bracket shell—but with the lower half missing.

On many lower half consists of the motor casing only. Or the motor casing partially enclosed by a pivoting flange.

An e-bike carbon frame illustrates how far bottom bracket shells have changed—in a relatively short period of time.

A key issue is that the specifications for each brand of motor are different.

Every e-bike frame, carbon or alloy, is designed to accept Shimano Steps, or Fazua, or Bosch and so on.

Bottom bracket shells, then, have become almost exclusively brand-specific, eclipsing even Cervelo, Trek, and Colnago’s (to name a few) attempt who released their own press-fit standard during the 2000s.

The motor bolts into the shell with the hinged flange covering the rear.

The top panels are open to allow free movement of the control cables which run up the down tube, behind the battery.

Simplified

Hub drives are usually installed in the rear wheel although e-bike transformation kits — which turn conventional bikes into e-bikes by replacing the front wheel with a hub drive wheel — are becoming more common. And many e-bike brands use front hub drives anyway.

The bottom bracket, then, consists of a standard splined or square taper spindle.

Or as exemplified in Gogoro’s Eeyo, an integrated spindle crank with cupped bearings that sports the innovative rear hub/battery drive.

FINAL COMMENTS

A good way to think about the bottom bracket shell is as the foundational tube, the base on which all other tubes depend, quite aside from its function as the container for the bottom bracket.

The rise of e-bikes has transformed the BB shell into an open bracket into which a mid-drive motor is bolted.

The nature of its function may have changed, but it remains a foundational component in bike frame design.